#Industry News

Odot IO applications in photovoltaic sintering furnace

The temperature of the photovoltaic sintering furnace is a control object with a large lag and time-varying nature.

Using the traditional PID control method, the control system has a large start-up amount and a long start-up time.

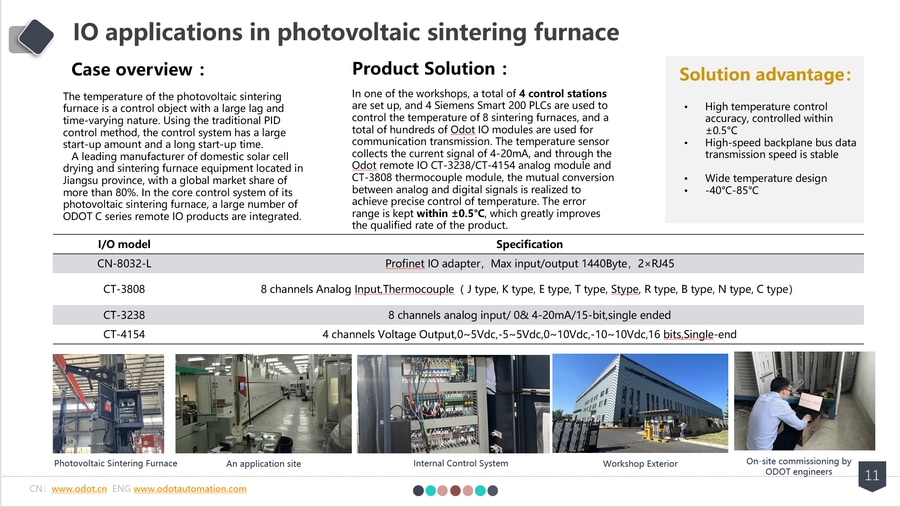

A leading manufacturer of domestic solar cell drying and sintering furnace equipment located in Jiangsu province, with a global market share of more than 80%. In the core control system of its photovoltaic sintering furnace, a large number of ODOT C series remote IO products are integrated.

In one of the workshops, a total of 4 control stations are set up, and 4 Siemens Smart 200 PLCs are used to control the temperature of 8 sintering furnaces, and a total of hundreds of Odot IO modules are used for communication transmission. The temperature sensor collects the current signal of 4-20mA, and through the Odot remote IO CT-3238/CT-4154 analog module and CT-3808 thermocouple module, the mutual conversion between analog and digital signals is realized to achieve precise control of temperature. The error range is kept within ±0.5°C, which greatly improves the qualified rate of the product.

Our Advantage:High temperature control accuracy, controlled within ±0.5°C