#Product Trends

Omnitrack Movement Solutions Spotlight – B21 Spring Loaded Ball Transfer B Bar

Omnitrack Movement Solutions Spotlight – B21 Spring Loaded Ball Transfer B Bar

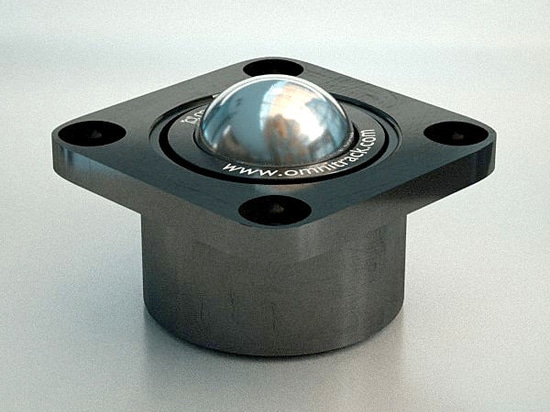

We’re aiming our spotlight this week on one of our more bespoke product lines in our range of movement solutions; the B21 Omnitrack Spring Loaded Ball Transfer B Bar.

Used primarily in machine & press beds, they utilise multiple spring loaded high capacity ball units housed in a solid steel bar for the movement & positioning of tools & dies. The patented ‘double recirculation’ internal mechanism provides the lowest coefficient of friction available in all ball transfers so heavy tools and dies can be positioned very accurately with relative ease. Once they are in place, the springs in the B21 B bar allow the ball units to retract into the machine bed when extra load is applied from above to clamp the tool in place. When relieved of the extra load, the ball units then raise the tool or die from the machine bed surface and permit ‘frictionless’ movement once more.

The B21 is 250mm [approx. 10”] in length and features 6 spring loaded ball transfer units providing a combined preload of 168 Kg. At one end of the B bar there is an M8 cap screw which holds the bar firmly in place when wound into a corresponding tapped hole in the press bed.

If the dimensions or load ratings of the B21 are not quite suitable for your specific application, most of the dimensions of the T and B bar ranges can be adapted so that they are tailored to a particular press or machine bed. A greater or fewer number of ball units can be installed into the bar depending on the optimum spacing you require to move the heavy tooling or dies.