#White Papers

Automotive

Development, Vibration Analysis & Testing

The duration of product development processes from concept to series production is getting shorter and shorter. This is particularly the case in the automotive industry, where the switch to electromobility is accelerating change. New components and the use of lightweight construction require extensive vibration analysis.

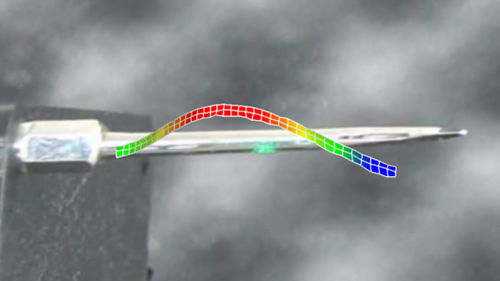

Even though the mechanical properties of components and entire component groups are increasingly and more precisely examined by numerical simulations, experimental measurements of physical objects are still required to validate these calculations. Non-contact measurement techniques such as laser vibrometry have the advantage that they do not influence the vibrations of the components and deliver excellent results in a very short time with little effort.

The superior signal quality of the Optomet infrared technology produces the best possible measurement results even on poorly reflective surfaces. This makes the devices suitable for measuring any component, regardless of its material or optical reflectivity. The Optomet’s ease of use and powerful measurement capability reduces development time.

Whatever your non-contact vibration application, be it in the wind tunnel, on the rotation test rig, in the acoustics laboratory, for experimental modal testingor for the development of components such as sensors or drives, the Optomet team will be happy to assist you in selecting the suitable vibrometry solution and implementing it.

Aeroacoustics:

Aeroacoustics deals with the noise caused by aerodynamic flow. Turbulent flow as well as flow through and around structures creates vibrations on components. These vibrations, in turn, are responsible for the generation and emission of sound waves, some of which people perceive as unpleasant. Ever stricter emission regulations also increase the need for noise-reducing designs.

Noise reduction is particularly important in the aerospace and automotive industries. Examples of noise include, engine noises on aircraft or wind noises on motor vehicles and high-speed trains. As other sounds of noise are more and more reduced or eliminated, as is apparent from the replacement of internal combustion engines in motor vehicles by electric drives, flow induced noise is perceived as more present and disruptive.

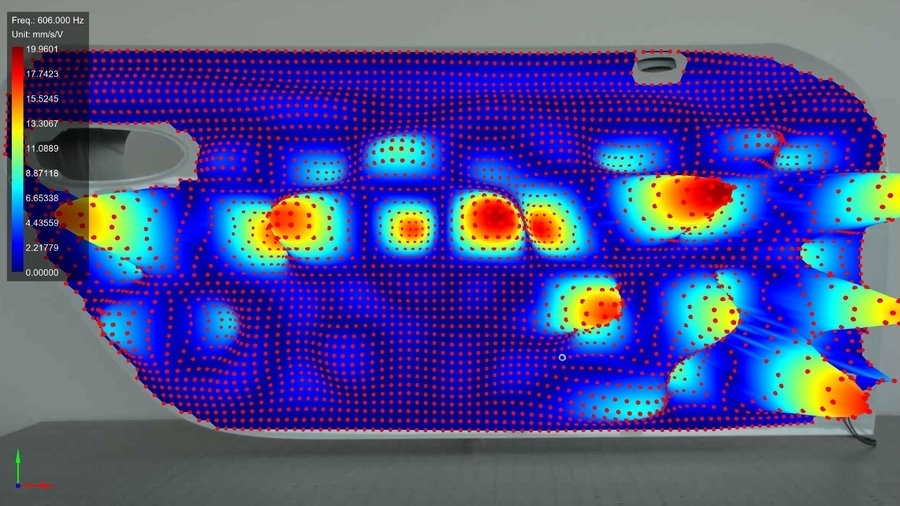

The airborne sound is measured by microphones or entire arrays of microphones. However, when it comes to identifying the possible sound sources, measurement methods with better spatial resolution, such as scanning laser Doppler vibrometry, are required.

With the Optomet laser scanning vibrometers, both small structures and entire vehicles can be examined without contact and with high accuracy. The user-friendly OptoSCAN software enables the measurement to be carried out quickly and offers a wide range of meaningful analysis and clear two-dimensional and animated displays for this task. For example, the correlation of the forms of vibration with the frequencies recorded in airborne noise can be used to draw important conclusions about the location and the type of sound generation, and suitable design measures for noise suppression can be taken.

The infrared laser technology (SWIR) of the Optomet scanning vibrometer produces a sufficient signal level for a reliable vibration measurement even at larger measuring distances of more than 10 meters. Even dark or reflective curved measuring surfaces can be measured without a reflection-enhancing treatment. Measurements through thick glass surfaces between vibrometer and measurement object are also possible without impairments.