#Industry News

Successful started-up of OSV M15 7K MDI in Bulgaria

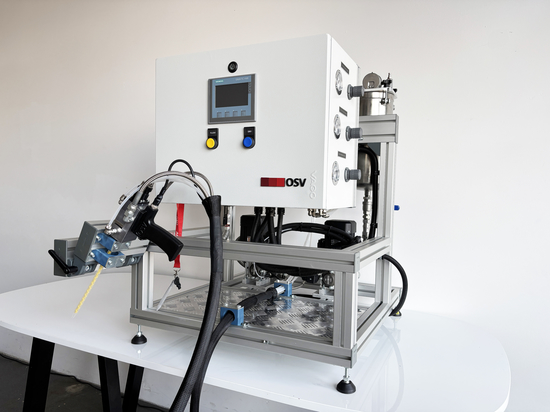

OSV M15 7K MDI — Hot-casting dosing machine for processing three-component polyurethane elastomers based on MDI

In the last week of February, OSV engineers started-up for our clients in Bulgaria the OSV M15 7K MDI — metering and mixing machine for processing three-component polyurethane elastomers based on MDI including three pigments and catalyst. During the start-up together with our customers we have casted around 500 kg of the different parts on different recipes and working modes. Main applications of the OSV M15 7K MDI are mining, automotive, heavy industry and agriculture.

OSV M15 7K MDI works on maximum output of 15 kg/min and it is equipped with three independent pigments’ lines and once catalyst metering line. PLC control panel, frequency inverters and some other electronic components are made by Siemens (Germany), ensure maximum product quality and process reliability in combination with user friendly interface. OSV M15 7K MDI machine is equipped with remote control unit which allows OSV engineers get connect to the machine if it is necessary for some technical support.