#Product Trends

Linear actuator connector configured online

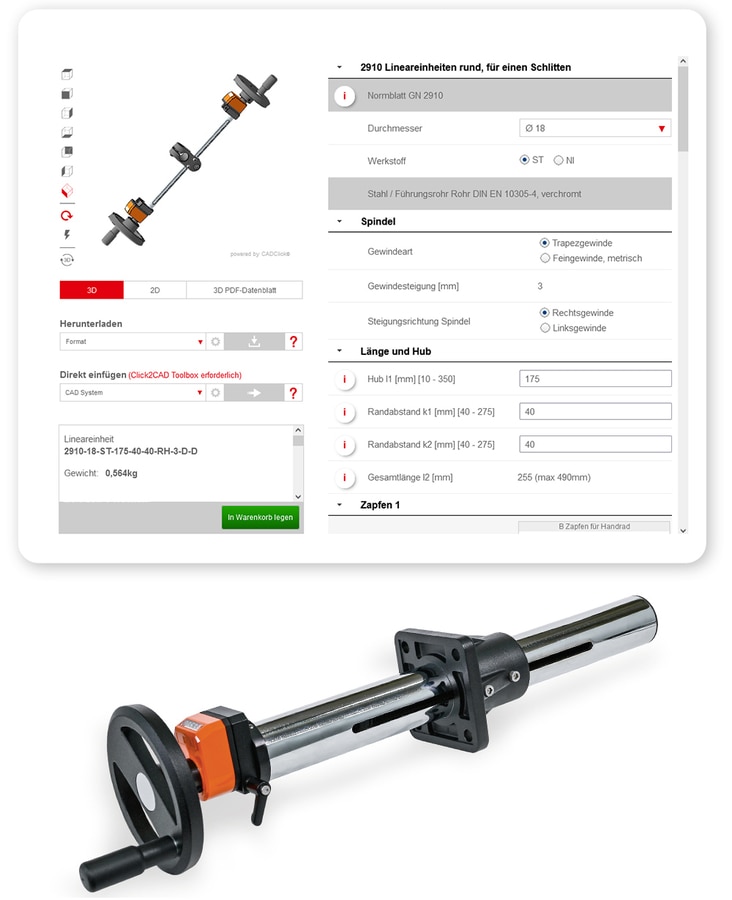

Ganter is repositioning itself for linear actuator connectors and will soon be offering connectors with individual specifications. The real-time online configurator makes this possible.

Linear actuator connectors have more different parameters than Ganter's Standard Parts strategy could cover — until now. The market leader in standard parts is now presenting a completely new concept that combines the benefits of Standard Parts with a wide range of customization options. This customer-centric strategy is made possible by the new online configurator, which can be used to specify the central parameters of a linear actuator connector and output them in real time.

The online configurator offers several advantages over the previous standard offering. In addition to the customizability, it makes the ordering process more efficient because the system immediately checks the selection for plausibility and indicates weight, price and delivery time in real time. The latter takes slightly longer than when ordering standard linear actuator connector, but the ability to enter individual specifications should outweigh this by far. Simultaneous transfer of options into 3D data sets enables the customer to immediately check whether the selected configuration fits into one's own design. This aspect is all the more valuable for time-critical tasks.

Important: the configurator is logically structured and provides a guide through the individual steps. The first step is to choose the linear actuator connector itself – six variants are available, with round or square cross-section, with one or two spindles, with different lengths, strokes, diameters and spindle types.

In the second step, decisions are made such as determining the shaft journals according to the axis design, for example. The next level is dedicated to accessories such as handwheels, clamping plates, position indicators or torque supports. And finally, the linear actuator connector itself can be selected.

The system automatically runs constant checks in the background to see whether the specifications entered are compatible and plausible. This makes it almost impossible to place an incorrect order.

And all values can be retrieved from the system and called out in spoken order numbers to ensure that the configuration can be traced. This means that further, identical deliveries can be made easily and reliably.