#Product Trends

Securely Fastened Loads

When something needs to be lifted, a crane, ropes or chains are needed – plus anchoring points on the load itself. Ganter offers a wide range of solutions here.

The classic and simplest lifting points are lifting eye bolts according to DIN 580, which are screwed into existing threads on the load. When threads are not possible, lifting eye nuts according to DIN 582 are used instead. Ganter offers these standard parts in two materials: steel and stainless steel.

However, a look in the Ganter portfolio reveals far better and stronger lifting points that are optimized for specific materials and – most important – easier to handle. In particular, the integrated RFID tags are worth mentioning as a special highlight. These make it possible to clearly identify specific lifting points during wear and safety inspections and manage them digitally and without system interruption.

Such RFID tags can be found in the lifting eye bolt GN 581 and the lifting eye nut GN 583, for example, which are still able to rotate around their vertical axis even after installation. Both of these options also identify load rings GN 586.1, although here the lifting eye can also be folded down. And thanks to the eye ring with ball bearing, load rings GN 5860 are fully rotatable even under load.

Load rings GN 587.1 are not screwed in but welded on. This load ring is also suitable for outdoor applications since the design of the weld-on block permits a closed seam that is safe from corrosion. The ring itself can be swiveled by 180 degrees, and an optionally integrated spring can secure it in any position.

The lifting point GN 589 for welding can accept loads from any direction and impresses with its minimal height. This is an extremely important feature when the maximum hook height of the lifting equipment is limited.

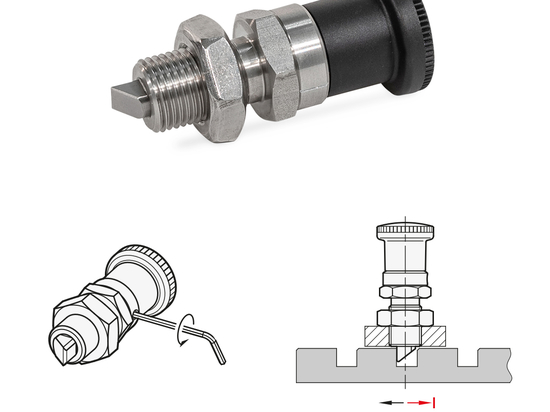

A practical alternative to threaded or welded solutionsis the mounting bolt solution, predestined, for example for devices or tools that change position frequently and quickly. GN 1130 operates according to the lifting pin principle with axial locking and a release button.

The new threaded lifting pin GN 1133 eliminates the time-consuming process of screwing into and out of the thread on the load. Rather than balls, this part uses threaded segments that are retracted and extended at the push of a button to create a positive connection. The integrated shackle, which rotates by 180 degrees, forms the connection to the lifting gear.

Speaking of shackles: You can find those in the Ganter product range as well. The shackles GN 585 are based on the US standard RR-C-271 and feature a significantly higher load capacity compared with the DIN version.

When it comes to lifting points, Ganter always has an eye on the details – making the parts even simpler and more efficient to use.