#Product Trends

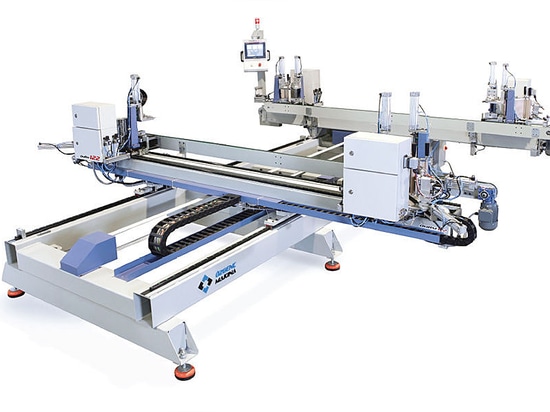

OMR 119 CNC PVC Profile Corner Cleaning Machine (2 Axis)

Application field:

Designed to clean the corners of PVC profiles from welding seals

General properties:

Used to clean the welded corners of PVC windows

CNC control system (2 axis)

Corner cleaning time 15-25 sec. depending on profile type

Movable 8.4” touch screen panel

Easy system for profile setup and programming

High cleaning performance with tools operated by servo control

High and standard quality in each profile surface with 9 cleaning tools

Up & bottom gasket hole drills

Up & bottom inner corner cleaning system (special patented design)

Up & bottom color – white surface cleaning blade system

Separate blades for white and laminated profiles

Adjustment of operating speeds to the desired speeds

Wide stand with brushes provides easy operation and protects profile surface from scratches

500 profile memory capacity

Multi language support

Shift processing capacity: 190 – 200 items / 8 hours

9 Tools :

1 - top gasket cleaner

2 - top colored profile surface cleaner

3 - top white profile surface cleaner

4 - top inner corner cleaner

5 - bottom gasket cleaner

6 - bottom colored profile surface cleaner

7 - bottom white profile surface cleaner

8 - bottom inner corner cleaner

9 - outer corner cleaning saw