#Industry News

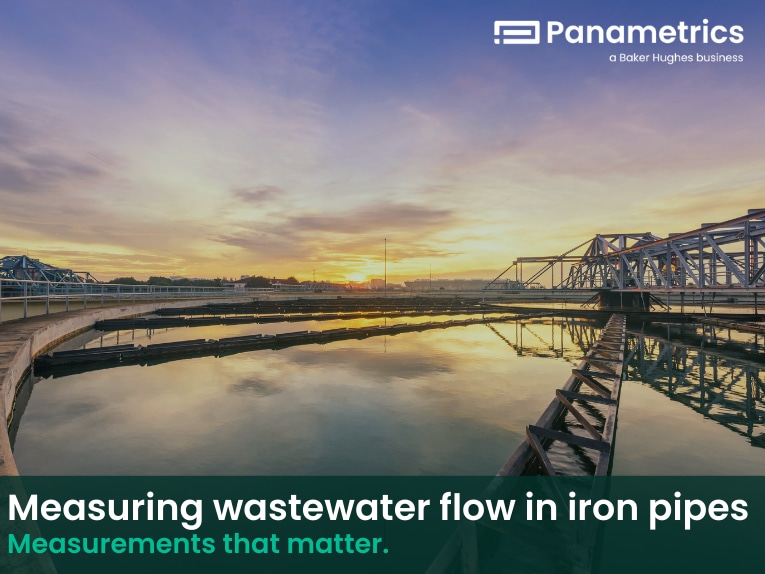

Measuring wastewater flow in iron pipes

Measurements that matter.

Summary:

The customer, based in Scandinavia, is a municipal association that supplies fresh drinking water, processes rainwater, purifies wastewater and responsibly disposes of household waste for half a million customers. Its activity is spread over several affiliated locations, with 15 sewage treatment plants, several hundred pumping stations, large-scale waterworks and several smaller local waterworks. These plants were built 50 years ago, however, the population has since doubled. Therefore, to drive network optimization, better flow monitoring is key.

Application:

The client wanted to understand if wastewater was equally distributed across two pipes at one of its wastewater facilities.

As was common practice when these plants were constructed in the 1960s and 70s the pipes were made from cast iron, which is traditionally very hard to measure.

- Wastewater

- Cast Iron DN300 to DN400 (12” to 16”)

- Temperature 15°C (59°F)

- Pressure 2-3 barg (29 – 43.5 psig)

Challenge:

Due to the age of the iron pipes the wall thickness was unknown - the properties of cast iron pipes, plus wear over the years results in uneven pipe thickness. In addition, the cast iron material, debris and corrosion inside the pipe could cause scatter. The customer had trialed several other products, but they failed to provide the reliability and accuracy required.

Solution:

A strong coded signal and its processing method combined with firm alignment and proper parameter settings were required for a reliable measurement. Panametrics’ Clamp-on ultrasonic measurement was ideal for non-intrusive flow measurement and had a strong track record of

successfully monitoring flow through cast iron pipes.

Each measurement spot was first verified with the Panametrics TransPort PT900 ultrasonic clampon flow meter. Once diagnostic results were satisfactory, an AquaTrans AT600 was permanently installed to provide 24/7 monitoring. This was set up with a 401 transducer 500kHz and CPL-1 to ensure continued accuracy.

Results:

The wastewater measurement was performed to check if the water was equally distributed over two pipes both of which were connected to the main meter. The sum of the two individual measurements matched the reading of the main meter, meaning the ultrasonic flow measurement was accurate. Not only did the customer achieve an accurate understanding of the flow volume distribution, it enabled the team to optimize its operations.

Benefits:

- No ingress or process interruption

- No contact with medium

- Easy to install and access

- Large rangeability and reliability