#Industry News

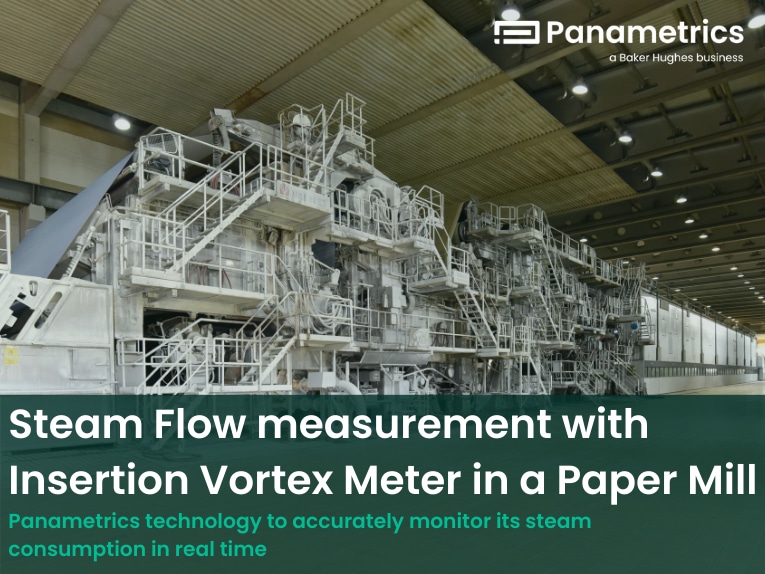

Steam Flow measurement with Insertion Vortex Meter in a Paper Mill

Panametrics technology to accurately monitor its steam consumption in real time.

Summary:

One of the largest paper mills in the Gulf countries (producing 325,000 tons annually, or 65 billion A4 sheets equivalent per year) was experiencing issues with existing flowmeters on its boiler’s steam line and wanted to explore alternative solutions.

Application:

Pipe size and material : 8” Sch 40, Carbon Steel

Steam flow range : 1 – 70 ton/hr

Steam temperature : 100 – 191°C (212 – 376°F)

Steam pressure : 1 – 12 bara (14.5 – 174 psia)

An existing Vortex flowmeter, which was providing inaccurate measurements, had to be replaced. The customer did not have an accurate picture of the actual steam flow measurement in the boiler system and did not know the reason for the malfunction. Following a site survey by Panametrics’ Channel Partner, it was concluded that the existing meter did not record temperature and pressure measurements and the meter vendor did not provide adequate technical support to resolve the flow measurement problem. Panametrics’ Channel Partner collected the application details together with the process data. Based on these and the sizing results, the team was able to propose a suitable solution.

Challenges:

Panametrics’ MV82 VTP™ insertion type multivariable vortex flowmeter with pressure and temperature sensors was proposed due to the density range and fluctuation in pressure and temperature. 2” insertion nozzles were recommended to fit the meter in the steam line. Panametrics’ flowmeter technology was implemented seamlessly, with the customer experiencing no down-time. Pleased with the solution, the customer is now able to accurately monitor its steam consumption in real time and better assess its boiler efficiency. It has asked Panametrics' to replace a further four vortex flowmeters at its site.

Benefits:

- Cost effective and accurate for large pipes.

- Wide rangeability, 1 to 70 ton/hour steam mass flow rate

- Single tap point for flow/temperature/pressure

- Easy mechanical installation

- No downtime and no periodic maintenance/calibration

- Installation and post order support by local team in UAE