#Industry News

Panametrics enables large US refinery to re-start flare operations in record time

Delighted with the end result, the customer is now exploring other opportunities to adopt Panametrics’ measurement technology.

Summary:

A large refinery in North America was about to start a large maintenance program. In preparation, several of the plant’s safety systems had to be routed to a single flare. However, the preferred flare had a malfunctioning steam system making flare control impossible.

It was a newly equipped steam line, and the customer couldn’t afford to wait several weeks or even months to get it fixed. The maintenance program could not begin unless the issue was resolved, i.e., the steam assist line running reliably and the flare fully operational.

Challenges:

Flare systems are safety devices designed to burn unwanted gas with a high combustion and destruction efficiency compliantly as per the EPA regulations.

Steam is used to cool the flare and mix hydrocarbons with air, facilitating effective combustion. Accurate and reliable steam measurement is essential to determine the correct volume of steam needed for optimal combustion.

Recognizing the potential impact on the local environment and the possibility of breaching EPA regulations, the customer wanted to avoid at all costs improper flare operations.

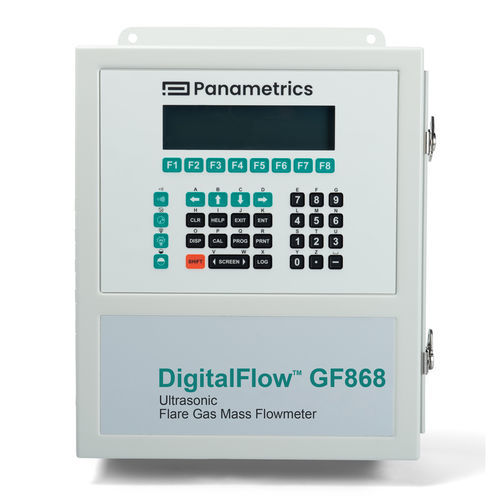

The customer originally selected an alternate ultrasonic flowmeter supplier to cope with a very aggressive lead time, but the selected meter failed to operate. It subsequently contacted Panametrics to find a fast and reliable solution.

Application:

- Fluid: Superheated steam

- Pipe size: 6” (DN150)

- Pipe material: SS304

- Process Temperature: 410°F ~ 560°F (210°C ~ 293°C)

- Process pressure: 150 psig (10.34 barg)

Benefits:

- Customer dedication

- Extensive expertise

- State of the art solution

- High reliability

- Local strong support

Solution:

Partnering with the customer, the Panametrics Team provided a solution that included the continued use of the existing flowcell, to keep costs and disruption to a minimum, identified the parts required and assembled a Service Engineer to be on-site to complete the job.

Within eight working days from the initial conversation, Panametrics GS868 electronics with its T5 extended temperature transducers were successfully installed, and the customer was able to start flare operations and commence its maintenance program within its original timeline. The steam flow meter has worked flawlessly since start up.

Delighted with the end result, the customer is now exploring other opportunities to adopt Panametrics’ measurement technology.