#Industry News

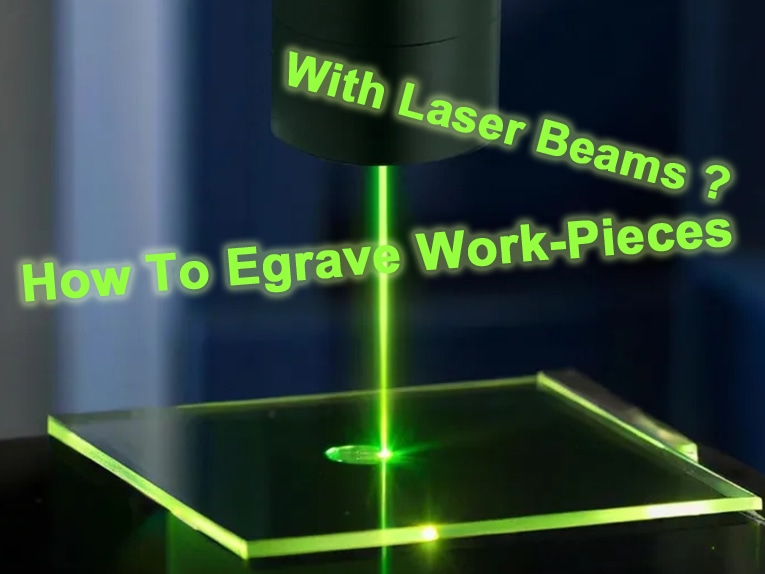

How to engrave work pieces with laser beams?

How to engrave work pieces with laser beams?

laser equipment is common to us, but have you studied the mystery of laser beams? Today we will explore the mystery of laser beams

Laser Art: Engraving the Magic of the Future

In the world of technology, in just 10 seconds, it showcases the magical charm of laser etching. A laser beam from a diode shuttles through a precise mirror system at a speed of up to 10000 millimeters per second, like a dancer crossing time.

The secret of fiber lasers is not just a game of light and shadow, but also the power of technology. Fiber laser, with its powerful energy, can engrave extremely complex patterns and easily integrate art into metal. The blazing heat of laser is like cutting butter with a hot knife, even hard titanium metal cannot withstand its sharpness. But interestingly, when you wave your hands in front of the laser, you can't feel any heat - because the wavelength of the fiber laser does not interact with organic materials.

The technology behind the revelation starts from diodes. Fiber lasers convert electrical energy into light energy, which propagates within the laser cavity. Through fiber cables doped with rare earth elements, the originally broad spectral light is converted into single wavelength light. Subsequently, the laser is emitted from the transmitter, guided by the galvanometer, and reflected by two mirrors, hitting the target with astonishing speed and precision.

This fiber laser with speed and passion can pulse up to 20000 to 400000 times per second, with each pulse lasting only one billionth of a second. At such a speed, even the fastest camera finds it difficult to capture its full view. The interaction between laser and materials produces ever-changing effects based on the different materials. For example, steel can present rich colors, while aluminum can only leave a pure white mark.

Fine art on aluminum, we witness the art of melting. This is a high-precision technology for removing surface materials from objects. By controlling the laser power, pulse frequency, and scanning speed, we can leave clear and accurate marks on aluminum materials. On stainless steel, we experienced more intricate carving. By reducing pulse width and energy output, we can create unique visual effects without damaging the material.

The charm of color, but the most stunning, is undoubtedly the color created on steel. This is because steel contains iron, which allows it to undergo special chemical reactions with lasers. By precisely controlling pulse width, energy output, and scanning speed, we can present colorful patterns on steel. This technology not only requires extremely high precision and stability, but also requires creators to have a profound understanding and unique insights into art.

The magic of technology and these magical machines have permeated every aspect of our lives, from consumer electronics to medical devices, from maker spaces to small studios. They are not only practical tools, but also a stage to showcase the charm of technology. They remind us that when technology meets art, the future can also become so magical and charming.

If you want to learn more about topics of interest, please contact us