#Industry News

ARTIFICIAL INTELLIGENCE: THE TRANSFORMATION OF PLASTIC RECYCLING

ARTIFICIAL INTELLIGENCE: THE TRANSFORMATION OF PLASTIC RECYCLING

Plastic recycling is one of the great challenges of our time. Plastic has become one of the most widely used materials globally, but it is also one of the most problematic in terms of waste. Currently, millions of tons of plastic are generated each year, most of which end up in landfills, oceans, and other inappropriate locations.

Plastic recycling is a key solution to reducing the environmental impact of this material, but it is not easy. It requires advanced technology and significant investment. The recycling industry, particularly regarding plastic and packaging recycling, has experienced a revolution thanks to technology, particularly automation in waste separation processes driven by the application of artificial intelligence (AI).

ARTIFICIAL VISION: MORE ACCURATE WASTE MANAGEMENT

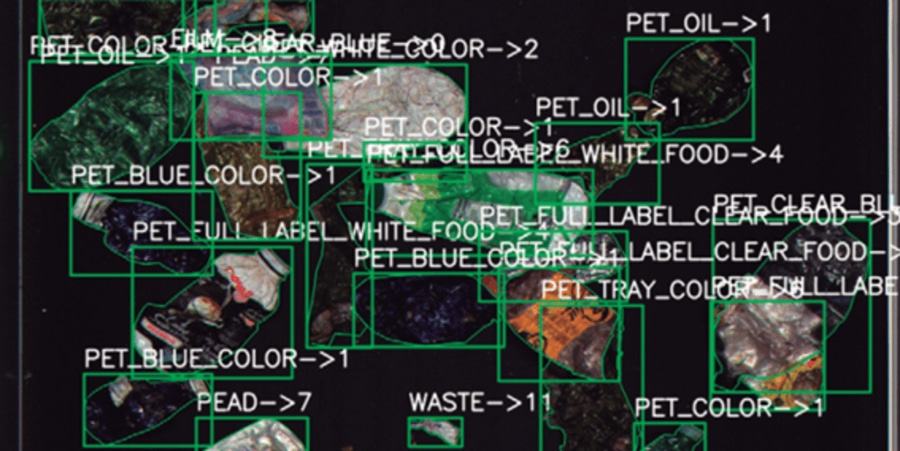

AI, and particularly artificial vision, has enabled much more precise automation of waste management. Using cameras and sensors, the technology can automatically recognize and classify different types of materials, allowing for greater accuracy in separating materials and a more efficient recycling process. It enables customization of the recycling process and obtaining higher quality materials.

Additionally, AI also allows for greater precision in quality control of recycled materials, reducing the risk of errors and the delivery of low-quality materials to customers. Lastly, it leads to greater flexibility in the recycling process, meaning that recycling plants can adapt to changes in material flows and sort new materials quickly and efficiently.

Artificial Intelligence and Artificial Vision are key technologies to enable machines to perceive, understand, act, and learn, as well as identify and classify objects through content analysis and interpretation of numerical or symbolic information.

PICVISA uses deep learning algorithms on images captured by cameras to accurately classify materials passing through a conveyor belt. The combination of these technologies allows the artificial intelligence and robotic systems developed by PICVISA to enhance waste selection capacity, maximizing material recovery and ensuring optimal quality for their subsequent transformation into secondary raw materials and valorization. At the end of the article, we will see an example of an application for a project where technology was programmed to identify specific waste.

PLASTIC RECYCLING: GLOBAL CONTEXT

Regarding countries lagging in plastic recycling, we find very concerning situations. According to ONU data, in Latin America and the Caribbean, only 4% of plastic waste is recycled, and much of it ends up in landfills, rivers, and oceans. Brazil, one of the most populous countries in the region and where PICVISA is already developing projects, produces the most significant amount of plastic waste globally after the United States and China and only recycles 1.28% of it.

The situation in African countries is similar: in many cases, the lack of infrastructure and non-existent waste management systems cause plastic waste to end up in dumps and landfills.

On the other hand, we find countries leading the plastic recycling ranking, such as Norway, recycling 97% of plastic packaging, and Germany, exceeding 80%. Portugal, although not at the top, has made great efforts in recent years to improve its recycling rate, and currently recycles around 35% of its plastic waste. The Netherlands is another notable example, with a highly efficient and technified recycling system that has achieved up to 81% recycling of its plastic packaging. The key to success in these countries has been investment in technology and the implementation of efficient waste management systems, including source separation and automation in recycling plants.

CUSTOMIZATION OF THE PLASTIC RECYCLING PROCESS

PICVISA is an example of how combining these technologies can improve waste plastic selection capacity at treatment plants. In one of our latest projects, we developed an ECOPACK optical separator that uses the latest artificial vision and AI technology to detect non-detectable impurities using NIR, such as silicone cartridges or Rhinomer-type packaging. The equipment is configured to classify the material according to its nature using three outputs and is already in production 24/7.

Impurities considered rejection (including silicones, Rhinomer-type packaging).

Impurities in the processed batch but valuable in another batch and recirculated to the process’s beginning (colors not corresponding to that batch).

Correct material continuing the recycling process.

Additionally, PICVISA has developed other AI-based solutions, such as the ECOPICK sorting robot, the ECOFLOW flow analyzer, and the Data + data platform.

In conclusion, the technification of plastic recycling and other materials is an increasingly pressing need and an opportunity to improve the efficiency and profitability of recycling plants, as well as to promote the circular economy and the sustainability of the planet. In this sense, companies like PICVISA are at the forefront of innovation and technological development, offering cutting-edge solutions that include Artificial Intelligence and contribute to improving waste management and environmental care.