#Industry News

APPLICATION SOLUTIONS FOR THE WOODWORKING INDUSTRY

Integrated components and systems

ACTUATION

Pneumatic cylinders, linear actuators with belt or ball screw transmission.

The Pneumax actuator range includes pneumatic and electric technology with a wide range of standard or customised solutions with bores ranging from Ø6 mm to Ø320 mm and strokes up to 6000 mm. Pneumax actuators are ideal for applications which require flexibility and precision such as the positioning of caps or stop guides, or combined with clamping elements, to clamp the components to be machined. Customised solutions designed to create integrated cylinder-solenoid valve systems for specific applications such as spindle selection for drilling heads.

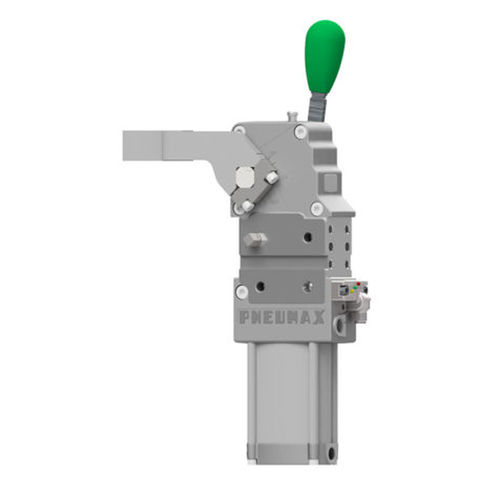

CLAMPING

Reference stop, stopper and roto-translating cylinders.

Over 45 years of experience in the woodworking sector have allowed Pneumax to design all the components used to ensure the panels being processed inside the production lines are placed correctly. An example of this are the over 190 versions of stop cylinders which ensure centesimal precision in maintaining their position during machining or the rototranslating cylinders which enable to work at different pressures and perform translation and rotation movement free from each other.

CONTROL

Pneumatic and vacuum systems management solutions.

The Pneumax range includes valves and solenoid valves with point-to-point electrical connection ideal for direct assembly on the cylinder and multipolar solenoid valve sets or serial systems that support all main communication protocols used in the sector. The valve assemblies are available in both engineering plastic or aluminium construction and designed to meet all the requirements with regards to size, weight and durability. Pneumax also manufacture 2 or 3-way shutter valves, poppet valves and solenoid valves for high flow air and vacuum applications.

SAFE & GREEN

Energy savings and safety automation.

Pneumax components are designed to ensure compressed air consumption optimisation and the safety of machines and operators. An example of this are the Safeline on-off and discharge valves with electro-pneumatic control and spring return, equipped with a diagnostic system for the valve status and with safety and redundancy functions, certified and compatible with ATEX environments. Double version valves are also a component classified in CATEGORY 4 according to ISO EN 13849, suitable for use in safety circuits up to PL=E.

PANELS AND SYSTEMS

Plug & play solutions to optimise pneumatic system management.

Panels, systems and integrated solutions are designed to house all the pneumatic circuitry internally, including solenoid valves which can assembled directly on the machine offering a compact solution. With regard to panel handling, an example are the circuits of directional valves/solenoid valves for suction and blowing control placed inside the suction cup holder or, in polishing, the systems composed of pads integrated with the pressure adjustment electronic systems.