#Product Trends

Shift in Motion: An innovative propulsion system for mobile machines

Manufacturers and operators of today’s mobile equipment often want a machine that does double duty: provides high tractive effort in the working mode and high maximum velocities when operating in the transport mode. These drivetrain requirements can be met through a wide array of traditional technological concepts, ranging from simple manual transmissions (shifted at standstill) to powershift or highly sophisticated power-split CVT transmissions. Each of these designs brings specific advantages,

Linde Hydraulics, based in Aschaffenburg, Germany and with U.S. headquarters in Canfield, Ohio, offers mobile-equipment OEMs and users another option with its Shift in Motion traction drive system.

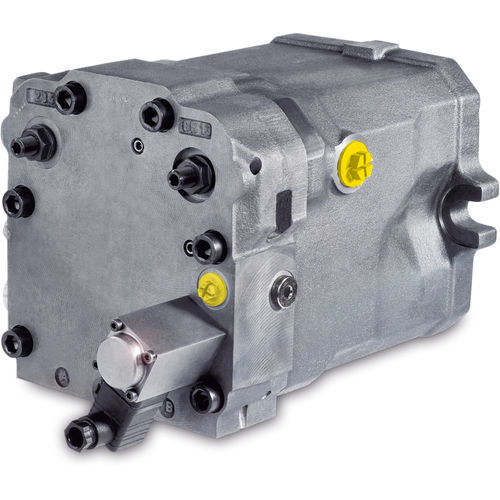

Shift in Motion (SIM) combines a stepless hydrostatic drive with a standstill manual transmission. The basic configuration includes a continuously variable hydrostatic rotating drive consisting of a Linde HPV-02 variable displacement pump and HMV-02 motor variable motor mounted on a standard manual transmission. The system is also equipped with an electrohydraulic shift actuator and is controlled with a Linde electronic control unit.

SIM synchronizes the drivetrain and permits comfortable gear changes while a machine is in motion. The actual switching operation in the standstill manual transmission is initiated via the electrohydraulically controlled actuator. The pump and motor bring the drivetrain to a no-load condition and the transmission is disengaged into the neutral position. The hydraulic transmission is then adjusted to the new ratio of the selected gear, the required gear engaged, and normal drive operations continue. The unit’s electronic control logic handles synchronization and continuously monitors actions.

The gears shift quietly and jerk-free in about half a second, thanks to electrohydraulic synchronization and the ability to adjust the drive component’s speed and torque. Thus, there is no need for multi-disc clutches and mechanical synchronizer rings, which increases the transmission’s efficiency. Shifting can be initiated by the driver or automatically, based on the vehicle and application. And with a CAN bus connection, the Linde ECU can also be used in tandem with the customer’s higher-level machine controller.

To minimize vehicle manufacturers’ implementation efforts, SIM was designed as a propulsion system that can be installed on conventional standstill manual transmissions without design changes: While the machine manufacturers select a gearbox of their choice, Linde Hydraulics supplies the essential SIM components and aligns them with application specifics and customer preferences. In addition to the high-pressure pumps and motors, it includes a SIM control valve for the transmission actuator as well as the electronic drive control.

With SIM, Linde Hydraulics provides mobile-machine manufacturers more freedom for their machine layout at low costs. The simple and straightforward gear changes mean that it is worth configuring the transport gear to a higher top speed. This lets the vehicle reach maximum speed using a lower drive and engine speed, which reduces both fuel consumption and noise emissions. SIM is particularly suitable for vehicles that often change between transport and operation, such as equipment that requires both high tractive effort and a high top speed above 25 km/hr (15 mph). Typical examples include harvesting, municipal and forestry machinery designed for a power range of 40 to 300 kW (54 to 408 hp).

This traction drive system applies electrohydraulic control logic to a multi-stage drivetrain that can shift gears similar to a traditional powershift transmission. It offers both the comfort of CVT drives and the compact dimensions of machines with manual transmissions, at prices below those of powershift transmissions. Thus, SIM helps address the market trend towards higher performance while reducing energy consumption, emissions, installation space and costs.