#Product Trends

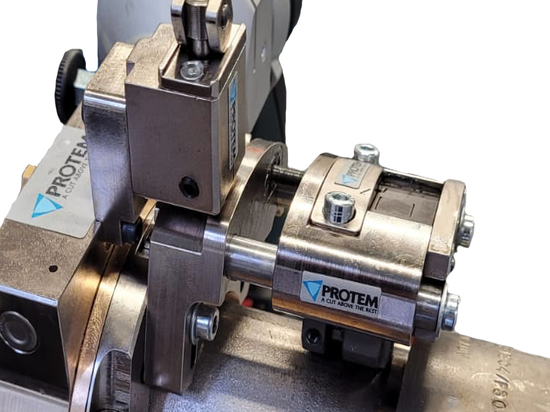

The SERCO XP: a portable equipment for facing flanges and valves

Have a look on its capacities!

Versatility is a highlight of the SERCO XP range of machines, allowing operators from various industries to perform a wide range of jobs on site:

- Repair of heat exchanger nozzle flanges

- Repair of flat, raised, and phonographic finish flanges

- Re-machining of gasket seals on tube sheets

- Repairing or making new ring grooves

- Re-facing of main steam inlet flanges

- Re-facing of ship hatch sealing surfaces

- Re-machining of rotary crane bearing surfaces

- Re-surfacing of large pump base housings

- Wind turbine tower section flange machining

The SERCO XP portable lathes are designed for uses in restrictive conditions.

As parallelism and concentricity settings are independent, only two stages are needed to set up the SERCO XP machines. Independent settings mean that the flatness does not need to be adjusted again after the concentricity has been set. The design allows a precision of 1/100 mm with a surface finish from Ra. 1.6 to Ra. 12.7.

We remain available to provide all information you may need at: contact@serco-tools.com