#Product Trends

July 2023: FOCUS on THE HIGH PURITY INDUSTRY - REQUIREMENTS AND CONSTRAINTS BEFORE WELDING

Special offer for Piping & Welding operators

Special offer valid from July 5th, 2023 to July 25th midnight:

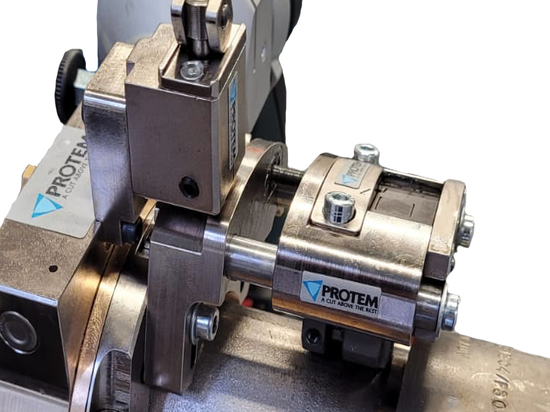

Protem Tube Facing & Squaring SE25 and/or SE65 with electric drive 220 V or 110V, transport box and one clamping collet.

The machine is delivered with :

- 1 corded 110 V or 220V electric drive or 1 cordless drive

- 1 facing tool holder with one carbide insert and screw

- 1 clamping collet (saddle) - diameter to indicate

- 1 hex key - 4

- 1 insert key

- operating manual

- transport box

Delivery terms: ex works

Payment: Prepayment required

Subject to goods being unsold

Ask for your promotional offer : contact@protemusa.com

* * *

The high purity industry requires stainless steel tubes with a very high level of cleanliness.

The quality of the weld will depend directly on the quality of the preparation.

For example, thin tubes should have their faces straightened before welding. By thin tubes, we mean tubes whose thickness does not exceed 3 mm.

The quality of the preparation will be crucial.

Protem Tube Facing & Squaring Machines use carbide inserts especially designed for machining thin tubes with low thicknesses.

Tube Squaring may be necessary, even if the tube has been cut perfectly straight and perpendicular.

The cutting blades used for orbital saws generally lead to the creation of a surface finish that may include scratches.

In the high-purity sector, such scratches are prohibited. This is why it is important to perfect the surface finish using a tube facing & squaring machine.

By squaring the tubes, geometrical and perpendicularity default are avoided and tiny burrs is also avoided.

A perfect squaring is necessary before any orbital welding job in order to guarantee the quality of the welding.

A tube facing/squaring machine must therefore combine a number of advantages:

Burr-free preparation

No tube deformation thanks to clamping collets that follow the shape of the tube

Extra-short clamping collets for use on micro-fittings, T-fittings and elbows

Ensure that the tube is perfectly straight before welding

Avoid soiling the tube by clamping on the outside of the tube

Remain reliable and lightweight, with flexible motorisation (Protem machines are available with electric or cordless motorisation)

Ensure consistent and repeatable preparation quality