#Industry News

Types of Sterilization Cycles in Autoclaves

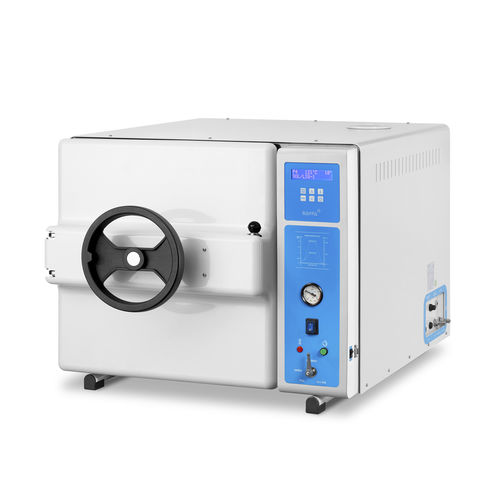

Explore the main sterilization cycles and learn how to select the appropriate one according to the type of instruments to be processed

Sterilization cycles in autoclaves are essential for effectively sterilizing laboratory equipment and instruments. Each cycle is designed to meet specific requirements and handle different types of loads, making it crucial to choose the appropriate cycle based on the type of instruments or components to be sterilized.

Here is a guide to the most common sterilization options and their applications:

1. Gravity cycle: Ideal for sterilizing simple solid materials. This cycle is the most basic and can be executed by any autoclave.

2. Vacuum or pre-vacuum cycle: Perfect for porous loads and materials that need more effective and uniform steam penetration.

3. Liquid cycle: As the name suggests, it is designed for sterilizing liquids. It is recommended for sterilizing bottles with culture media or aqueous solutions.

4. Drying cycle: Ideal for sterilizing glass and instruments that need to be completely dry after sterilization.

5. Fast cooling cycle: Ideal for high-turnover laboratories, whose instruments need to be handled immediately after sterilization.

6. Isothermal or low-temperature cycle: Perfect for sterilizing heat-sensitive materials.

7. Short or flash sterilization cycle: Used in situations requiring rapid sterilization for immediate use of the instruments.

8. F₀ cycle: Based on the concept of thermal lethality, precise calculations are used to ensure the destruction of microorganisms.

9. Pressure support cycle: Ideal for processing liquids or sealed containers, such as packaged food or pharmaceuticals.

10. Ramp cycle: Designed for products requiring slow and controlled heating, allowing independent temperature segments to be programmed and the temperature increase rate between segments to be defined.

11. Product life cycle testing cycle: Designed to validate the durability and resistance of products subjected to multiple sterilization cycles.

At RAYPA, we are committed to offering the most advanced sterilization technology to ensure maximum safety and efficiency in your processes. If you have any questions, contact us and we will help you find the perfect autoclave for your needs.

For more information, visit our full article.