#Industry News

ROEMHELD at the Euroblech: Quick, convenient and safe changing of heavy moulds and dies

• Powered changing carts adjustable in height, with a wide selection of roller and ball bars with product configurator

Laubach, 21. August, 2018. Components for quick and safe changing of heavy dies are to be unveiled by the ROEMHELD Group at the Euroblech. Transport carts are used to manoeuvre large loads quickly and effortlessly and ergonomically, and carrying consoles facilitate insertion into the press and the punching system. Ball bars and roller bars allow the dies to be comfortably guided and positioned over tables, areas and feeders. With their die clamping and die changing technology, as well as an extensive range of hydraulic, mechanical, electromechanical and magnetic clamping elements, ROEMHELD consider themselves experts in the optimisation of setup times for forming technology.

An expansive portfolio from the ROEMHELD changing technology range ensures that the group can provide cost-effective solutions for a broad spectrum of sophisticated applications. Four different configurations of transport carts will be presented on the exhibition stand for various loads, with additional demonstrations of supported, hanging and swivelling carrying consoles, as well as freely configurable roller bars and ball bars. Overall systems can be configured for efficient die changes using a combination of wedge clamping elements from the new, comprehensive range of products and the appropriate hydraulic supply. The ROEMHELD Group presentation will be held at the exhibition in Hall 27, Stand H128.

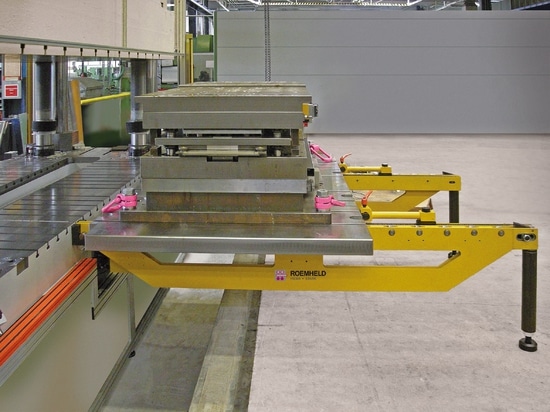

Changing carts: Safe transport of heavy loads

Dies weighing in excess of one and a half tons can be manoeuvred with changing carts (photo 1). Four different models will be exhibited by the group at the Euroblech: the manually operable RW series designed to carry 500 kg and 1,000 kg, and the electrically driven RWA type walking and lifting cart with a maximum load of 1,600 kg.

All versions feature extensive safety equipment, including an automatic docking station with slip protection: with the cart connected to the station, dies can be effortlessly guided and positioned in the changing table via ball inserts. The balls are then lowered during docking to prevent slipping. Safety bars may also be fitted for transport. Height of the changing table can be adjusted by the operator to suit his respective requirements by way of a hydraulic lifting column.

An optional auxiliary drive is available for cart models up to 1,000 kg, allowing a travel speed of 2 km/h. Speed of the RWA walking and lifting cart for heavy dies can be steplessly adjusted up to a maximum value of 5 km/h. Powerful and durable battery systems supply the changing carts with power.

Carrying consoles: Handling aids for the insertion of heavy moulds

Heavy dies exhibiting a weight of up to 32 t which are transported by crane or forklift truck can be manoeuvred quickly into the press table with ROEMHELD carrying consoles (photo 2). The dies are simply placed onto the consoles, and from there inserted via integrated transport bars. Separate versions either with or without drive are available in this regard, depending on respective weight of the die.

Attachable carrying consoles which can be hooked onto the suspension hooks in pairs are available for loads of up to 250 kN. This allows application on various machines and they are ideal for initial installation, as well as for retrofitting. Swivelling consoles are recommended wherever space is restricted in front of the press. These are fixed securely onto the press table and can be folded completely into the table again when not required. Loads of up to 60 kN are possible in this regard.

Versions with additional electrical drive and support feet are available for die weights of up to 32 t, further increasing stability of the carrying console. These can be adjusted ± 60 mm in height in order that any unevenness in the floor can be easily compensated.

An automated changing station is included in the changing technology range from ROEMHELD for loads of up to 32 t. This manoeuvres the new die to the press table in a linear motion and pushes the existing die out of the machine to the rear. Particularly short setup times can thus be realised.

In addition to standard components, the group also develop customised stations and carrying consoles, for example for heavy moulds or for automated processes.

Roller bars and ball bars: Simple positioning in the press

Roller bars and ball bars (photo 3) are fitted in the slots of a machine table to facilitate the guidance and positioning of dies onto surfaces. Whether aluminium or steel, hydraulic or pneumatic, for use in T-slots or rectangular slots: an extensive selection of bar types is offered. The length, slot width and depth, as well as distances between balls or rollers can be individually adapted.

For hydraulic roller bars, lifting pistons raise all rollers individually, or the entire bar depending on the respective design, until the die is clear of the table plate and can be shifted effortlessly. This allows loads of up to 160 kN per meter, depending on the respective design. Ball bars can move loads of up to 70 kN/m.

Bars featuring spring preload are also available for lighter and medium weight dies. In this version, rollers or balls protrude slightly over the table plate. They are pushed into the body of the bar as the die is clamped and then close flush with the table plate.

Assembling roller bars and ball bars independently using the online configurator

An online configurator allows independent assembly of roller bars and ball bars with the respectively required product characteristics, creation of dimensional drawings and subsequent queries to be sent directly. The program can be obtained using the following address https://www.roemheld-gruppe.de/productconfigurator/?lang=en.

Special requirements which cannot be acquired using the comprehensive configurator are provided by ROEMHELD with special custom-made products, such as bars featuring greater lift, or for other slot types.