#Product Trends

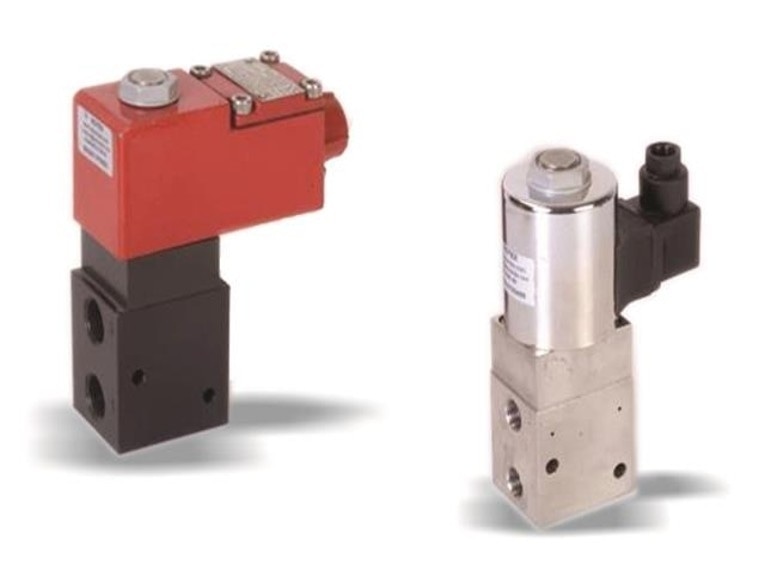

Pneumatic solenoid valve - The Beauty of engineering

In the world of industrial automation Pneumatic solenoid valves a critical role in controlling the flow of air gas.

Pneumatic solenoid valves are a crucial component in many automated systems and have a wide range of applications across various industries. These valves are used to control the flow of pressurized air in a system and can be found in everything from manufacturing machinery to HVAC systems

A pneumatic solenoid valve consists of a coil, a plunger, and a valve body. When the coil is energized, it creates a magnetic field that moves the plunger and opens the valve. When the coil is de-energized, the plunger returns to its original position, closing the valve. This simple yet effective mechanism allows pneumatic solenoid valves to open and close rapidly, making them ideal for use in fast-moving automated systems

There are several types of pneumatic solenoid valves, each designed for specific applications and requirements. The most common types are:

2-way pneumatic solenoid valves

These valves have two ports and can either open or close the flow of air. They are used for simple on/off control and are the most basic type of pneumatic solenoid valve.

3-way pneumatic solenoid valves

These valves have three ports and can divert the flow of air from one port to another. They are commonly used to switch between two different air sources or to control the flow of air to multiple outlets.

Pneumatic solenoid valves are highly reliable and efficient, making them an essential component in many automated systems. They are also relatively simple to install and maintain, making them a cost-effective choice for many applications.

One of the main advantages of pneumatic solenoid valves is their ability to operate at high speeds. They can open and close in a fraction of a second, making them ideal for use in fast-moving automated systems. This speed of operation also makes them suitable for use in applications where a rapid response is required, such as in emergency shutdown systems, pulse purge applications, etc

Another outstanding characteristic of pneumatic solenoid valves is their versatility. They can be used in a wide range of applications and are available in a variety of sizes and materials to suit specific requirements. They can also be easily combined with other pneumatic components, such as cylinders and actuators, to create complex automated systems.

Pneumatic solenoid valves are also highly durable and can withstand a wide range of operating conditions. They can operate in extreme temperatures, high pressures, and harsh environments, making them suitable for use in many industrial applications

In summary, pneumatic solenoid valves are an essential component in many automated systems. They are highly reliable, efficient, and versatile, and can operate at high speeds and withstand a wide range of operating conditions. If you are considering using pneumatic solenoid valves in your automated system, it is important to choose a reputable supplier that can provide high-quality valves that meet your specific requirements

Rotex Automation is the leading manufacturer and supplier of Solenoid valves and other fluid control systems. Rotex offers a broad range of pneumatic solenoid valves (commonly known as Air solenoid valves) that include Electric air solenoid valves, high-pressure pneumatic solenoid valves, and compressed air solenoid valves.