#Industry News

Industrial wastewater treatment with liquid solid separation equipment

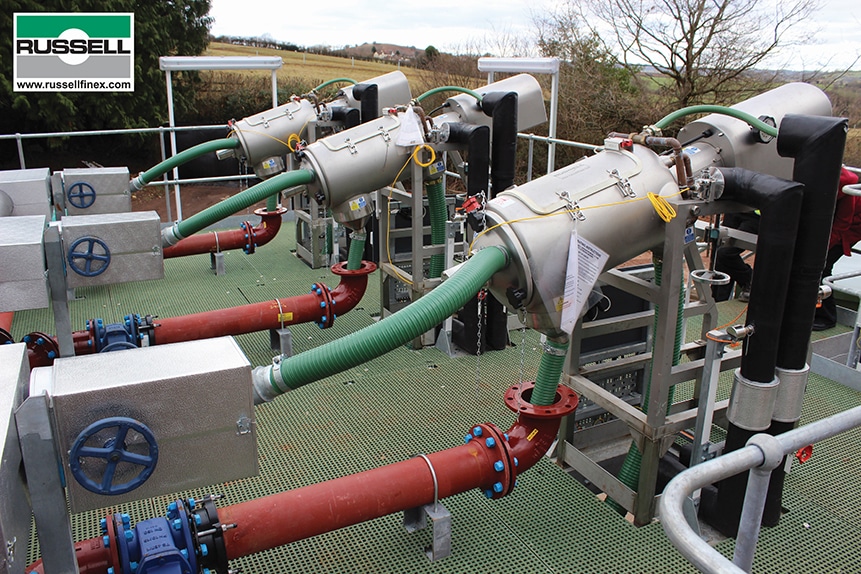

Reduce disposal costs with mechanical effluent treatment technologies with the Russell Liquid Solid Separator™

Wastewater treatment and disposal costs are forecasted to rise by around 5% per year over the next five years. With this in mind, companies across a variety of industries are seeking alternate methods to optimize their wastewater treatment processes. Water plays a large role in the day-to-day operations in manufacturing and construction, chemicals, food and beverage, agriculture and paper and pulp industries, with varying degrees of effluent treatment necessary to meet environment compliance in terms of discharging liquid effluent and wastewater or, in some cases, paying for offsite disposal and treatment.

Effluent disposal costs

The costs associated with treating and recovering industrial wastewater (also known as trade effluent) largely depends on the size of the facility and amount of water used. In most cases, plants using less than 100,000 gallons will pay significantly more per unit to treat or dispose of their effluent than those with higher flows. Naturally, many of these facilities with lower wastewater flow rates may not have the capacity for a separate effluent plant, or large-scale water treatment systems, meaning significant costs are paid to outsourcing treatment and disposal, or through surcharges for effluent discharge.

Primary water treatment

For this reason, a general water treatment process is recommended to be put in place to turn wastewater into an effluent that can be either returned to the water cycle with minimal environmental issues or reused. This starts with the collection of wastewater in a septic tank, where it is directed to a treatment area for odour control and screening, removing larger objects and solids that could block or damage downstream equipment and processes. The water then enters primary treatment, where it is stored in tanks and subjected to dissolved air filtration (DAF) – a water treatment process to extract suspended matter such as solids and oils. These solids settle on the surface and are removed, with clarifiers being a common system used for this stage.

Secondary and tertiary water treatment

Secondary and tertiary treatment is then applied to the wastewater, to remove further organic matter and chemicals. Microorganisms (also known as ‘seed sludge’) and chemical coagulants or flocculants can be applied at this stage, forming large particles of waste matter that can then be removed.

Options for mechanical removal of solids from effluent

The Russell Liquid Solid Separator™ is a compact and affordable solution to removing solid matter from wastewater streams. Designed as an efficient alternative to traditional liquid solid separators, this multi-purpose centrifugal separator has the ability to deal with soft and fibrous oversized solids, achieving high-capacity separation on fine meshes down to 20 microns.

These compact units are capable of handling high flow-rates of liquids and slurries - up to 100,000 litres per hour – despite having a very small footprint. Therefore, they can be conveniently installed in an existing wastewater treatment process, ideal for facilities that require high-capacity filtration where investment into larger separation is not viable. The units are simple to operate, and quick and easy to strip down and clean by a single operator, significantlflowrates downtime aflowratesosts. Furthermore, the Russell Liquid Solid Separator™ has been designed to run with lower power consumption than comparable units, further reducing running costs.

Features & Benefits

• Increase your productivity - Capable of handling high flow rates of liquid slurries up to 100,000 l/hr

• Reduce your costs - Liquid Solid Separators™ reduce loss of good product and disposal costs of effluent streams

• Operator friendly - Simple to operate and tune for optimum separation quality

• Easy cleaning - Stripdown and assembly easily accomplished by one operator. Spray bar system available for backflushing the mesh either during or at end of a production run

With 85 years of experience applying fine mesh separation technology to industrial applications, Russell Finex offers a wide range of innovative liquid solid separation equipment and self-cleaning filtration technology for wastewater treatment. To find out more, contact Russell Finex today.