#Product Trends

The future of sheet metal working redefined

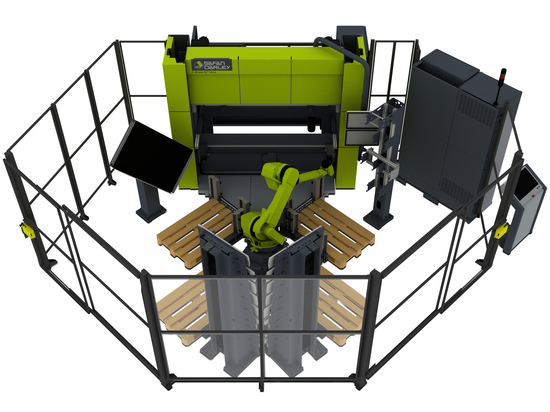

New H-iBrake press brake series

With the new and innovative H-iBrake press brake series, SafanDarley is redefining the future of sheet metal working. The H-iBrake is designed to take companies' production to the next level and be successful at the lowest possible cost. This is achieved through advanced drive technology, increased approach and pressing speeds, optimum precision and energy regeneration, among other things.

More efficient, safer and more sustainable

The H-iBrake uses the latest energy regeneration technology, which ensures less heat generation and very high energy efficiency. With sustainability in mind, a new drive system with integrated intelligent control is being used. This has reduced the size of the entire drive system with minimal energy consumption. The new drive system optimises speeds in each process step and reduces cycle times. A step has also been taken in the area of safety with the introduction of an adaptive safety system. This integrates maximum safety for operators and increases productivity. All machines using it are also equipped with new modular support arms.

The latest drive technologies

The H-iBrake is equipped with the latest drive technologies, which means fewer components resulting in lower maintenance costs. This also ensures unprecedented reliability and higher uptime. The applied technology covers the entire press brake range, delivering power and precision over the full range of tonnages. Whether working with light or heavy sheet metal, the H-iBrake ensures optimum performance in all cases.

Improved performance, financially attractive

Besides improved performance, the H-iBrake is also financially attractive. Its modular construction has resulted in an attractive price-performance ratio. In addition to lower purchase costs, using the H-iBrake also ensures lower energy consumption, which reduces emissions on the CO2 performance ladder. The design focuses is on using energy as efficiently as possible. Not only in consumption, but where possible also in feed-in which can significantly reduce operational costs.