#Product Trends

SANDVIK OPTIMINE® VISUALIZES THE MINING PROCESS

Sandvik continues to develop and enhance its advanced automation offerings. Transparency of the mining operation has long been a challenge. Sandvik OptiMine® allows you to compare a mine model with the actual layout of your mine and enables continuou

Sandvik OptiMine® is a modular information management solution that offers a real-time view of your underground mining operations. Suitable for all mining applications and the entire mobile fleet, including equipment supplied by other OEMs, the solution is designed to provide real-time tracking and production management tools for controlling both manual and automatic mining operations. Sandvik OptiMine® modules can be combined as needed to build up the required functionality and to optimize your mining operations. With open interfaces, the solution can also be integrated to other mine IT systems.

The two latest modules in the offering are:

3D Mine Visualizer

Based on the 3D scanning results, Sandvik OptiMine® 3D Mine Visualizer brings a three-dimensional model of your mine layout directly to your office. 3D mine visualization significantly enhances comprehension of large mining environments. One of the key benefits of 3D mine visualization is how it enables users to more effectively communicate and interpret data around the current situation and future plans for the mining environment.

Situational awareness is improved, as information about the mine can easily be studied and understood at a glance. 3D mine visualization is a valuable tool in operations planning, analyzing problematic areas and tracking mine development over time.

Drill Plan Visualizer

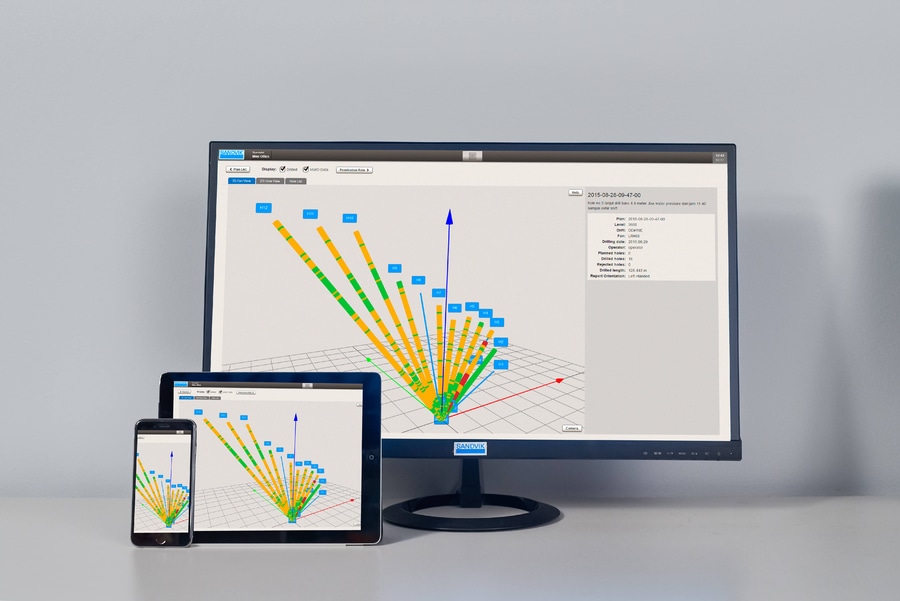

Sandvik OptiMine® Drill Plan Visualizer is an easy to use visualization tool for production and rock support drilling.

In the Sandvik OptiMine® Drill Plan Visualizer, drill plans and drilling results are visualized in a user-friendly and informative way, giving you the tools you need to compare drilling results to production drilling and bolting plans.

Drilling plans and bolting scenarios can be easily created, modified and edited for the most optimal results. With a web-based user interface, information on the planned and actual drilling is available anywhere, anytime and with virtually any connected device.

Drill plans are transferred to the drill automatically and actual, real-time drilling data is immediately available in the production control system. And, as per other Sandvik OptiMine® modules, Drill Plan Visualizer data is available for other mine IT systems.

For production drilling, Sandvik OptiMine® Drill Plan Visualizer shows existing plans and actual drilling results in a 3D format, including measurement-while-drilling (MWD) data, when available. MWD data is also available in 2D graphs for more detailed, alternative analysis of the drilling results. The tool's intuitive user interface ensures that the creation and editing of new drilling plans is convenient and quick.

These two new modules complement the current offering of Sandvik OptiMine® Monitoring and Reporting, Scheduler and Task Management and Location Tracking, which are used in mines in Australia, North and South America, Africa and Europe.

Sandvik Group

Sandvik is a high-tech and global engineering group offering products and services that enhance customer productivity, profitability and safety. We hold world-leading positions in selected areas – tools and tooling systems for metal cutting; equipment and tools, service and technical solutions for the mining and construction industries; products in advanced stainless steels and special alloys as well as products for industrial heating. In 2016, the Group had approximately 43,000 employees and sales of 82 billion SEK in more than 150 countries within continuing operations.

Sandvik Mining and Rock Technology

Sandvik Mining and Rock Technology is a business area within the Sandvik Group and a global leading supplier of equipment and tools, service and technical solutions for the mining and construction industries. Application areas include rock drilling, rock cutting, crushing and screening, loading and hauling, tunneling, quarrying and breaking and demolition. In 2016, sales were approximately 31 billion SEK with about 14,000 employees in continuing operations.