#Industry News

ASTM B117 Salt Spray Testing -Walk-in Temperature Humidity Integrated With Salt Spray Chamber

ASTM B117 is a salt spray test standard developed and published by the American Society for Testing and Materials (ASTM) Technical Committee on Standardization, and is an important test method for assessing the corrosion resistance of materials.

In daily production and use, the environment has a great impact on products, especially into the ocean and other humid environments, equipment and metal materials for a long time in this humid environment will face severe corrosion and oxidation problems.ASTM B117 is a salt spray test standard developed and published by the American Society for Testing and Materials (ASTM) Technical Committee on Standardization, and is an important test method for assessing the corrosion resistance of materials.

Standard Overview

ASTM B117 is a standard protocol for the operation of salt spray installations designed to simulate the corrosion risks to which metallic materials are exposed in marine environments, humid climates, and other conditions. The standard was developed by ASTM International to evaluate the corrosion resistance of metals and their coatings and to provide guidance on material selection and surface treatment techniques.

The ASTM B117 standard applies to salt spray resistance testing of any material, open or sealed, such as coatings, metal alloys, plastics, rubber, etc. The standard is designed to assess the corrosion resistance of materials. Through the salt spray test, the degree of corrosion resistance of a material can be assessed to determine its feasibility for adoption in marine environments or other harsh environments.

Test conditions and parameters

Temperature control: The test chamber needs to be maintained at 35°C (±2°C).

Salt spray solution: Use 35g of sodium chloride dissolved in one litre of deionised water.

pH Control: The pH of the salt spray solution should be maintained at 6.5 to 7.2.

Exposure time: usually 24 hours as a basic, with 96 hours, 240 hours and 600 hours as the most common evaluation lengths

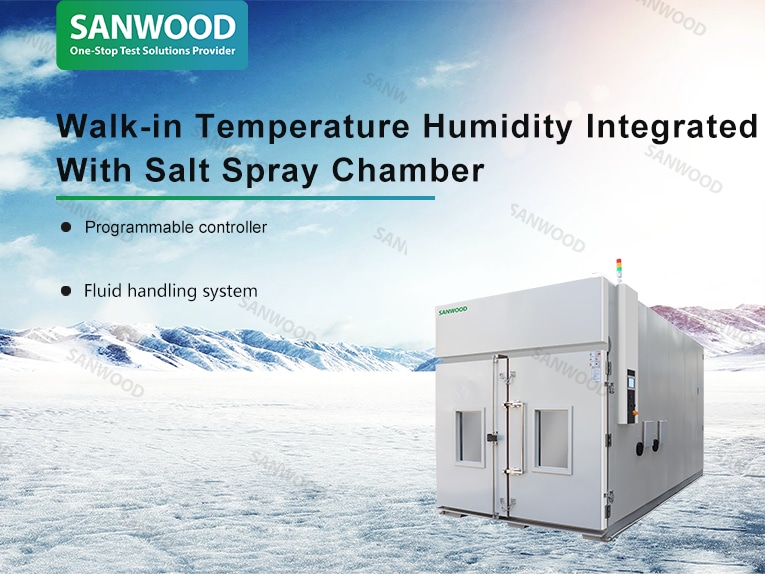

Walk-in Temperature Humidity Integrated With Salt Spray Chamber

Parameters of Sanwood Technology -Walk-in Temperature Humidity Integrated With Salt Spray Chamber

Temperature range:0°C~+85°C

Humidity range:20~98%R-H

Temperature Deviation:± 2°C

Temperature uniformity: ≤ 2°C.

Temperature fluctuation:± 0.5°C

Salt spray sedimentation: 1~2mL/80cm2-h The above indicators are at atmospheric pressure, unloaded conditions, from the inner wall of the box 1/10 space test

Sanwood Technology -Walk-in Temperature Humidity Integrated With Salt Spray Chamber features

Composite nozzle: solvent and compressed air in the nozzle fully mixed, through the nozzle will be sprayed into a corrosive mist.

Programmable controller: true-colour LCD touch screen programmable controller R232 interface and PC directly connected to the control accuracy: ± 0.1 ℃.

Fluid handling system: the most suitable fluid channel is designed through the fluid simulation simulation before production.

Sanwood Technology's salt spray test chamber can help evaluate the product's ability to withstand wet environments by simulating wet and salt spray environments such as the ocean.

The ASTM B117 test standard provides a standardized test method for quality control and production of materials. And Sanwood's salt spray test chambers strive to meet the requirements of the ASTM B117 standard in terms of design, functionality and performance parameters to ensure that they can provide accurate and reliable test results. If you need more details, please feel free to contact us.