#Industry News

The shredding of hazardous waste

Hazardous waste and toxic-harmful waste are our daily bread!

An important company based in Emilia Romagna, specialised in the recovery and disposal of special hazardous industrial waste turned to us for a solution for the shredding of hazardous waste for bulk reduction, in line with 4.0 Industry requirements.

I

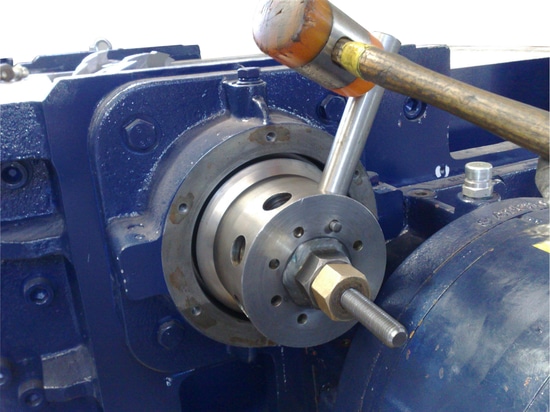

n view of the type of application, a twin shaft shredder from the 2R series, 150 HP, with hydraulic drive, fitted with 4x75 mm tips, was offered and is currently being installed and tested.

The shredding body is fitted with a shredding chamber that is 1,500 mm long and 1,100 mm wide, designed to accommodate the irregular and heterogeneous nature of waste fed into the hopper.

But what is hazardous waste? The list is extensive and includes:

• waste from chemical industrial processes;

• metallurgical industry waste;

• waste from electric and electronic devices;

• solvents;

• waste oil;

• batteries and accumulators;

• waste from medical and veterinary activities;

• waste from leather and fabric production;

• waste from the cosmetics industry;

• waste paint and varnish; waste ink;

• agrochemical waste containing hazardous substances.

The list of waste is prepared in accordance with article 1, letter a), of directive 75/442/EEC on waste and article 1, paragraph 4, of directive 91/689/EEC on hazardous waste.

Accessories

The offering is not limited to the shredder and includes different accessories that complete and further enhance it:

• a loading hopper with a 4 kW hydraulic RAM;

• a support frame with handrail and access ladder;

• an unloading belt;

• electric panel with control panel.

The RAM

The hydraulic RAM is an indispensable accessory in some applications and this is especially the case with industrial waste. It is fundamental for pressing material onto blades inside the loading hopper, for preventing bridge effect and floating, so that shredding performance levels are not compromised.

Support frame

In addition to supporting the shredder, following the suitable evaluation of static loads at play (the machine body alone weights 10 tons), the support frame is fitted with a walking deck, hand rail and access ladder with foot irons for accessing the shredder with ease for control and ordinary maintenance operations.

Bidirectional unloading belt

Supply includes a conveyor belt with metal shutters that are 7 m in length. What makes it special is the possibility to determine the direction of unloading: a selector fitted onto the command panel enables the client to decide whether to unload to the right or left.

Electric panel

A single electric panel controls and commands the entire shredding cycle. The supply responds to some requirements set forth in the 4.0 Industry paradigm: PLC, HMI display, remote assistance and remote diagnosis.

In this case, the client is tasked with interconnection and integration, although SatrindTech offers its partnership as a provider of complete solutions that fulfil all 4.0 Industry requirements, even providing the client with bureaucratic assistance.

Our shredding applications

The shredding of hazardous waste is just one area of industrial waste treatment in which we are specialised.

SatrindTech designs and supplies complete shredding systems for urban waste, bulky waste and WEEE, for the plastic and rubber industry , the food industry, as well as for the treatment of tyres (cars and trucks) and the entire automotive world.

The treatment of toxic-harmful waste is another key area in which the application of solutions for environments in which there is an explosion hazard, and therefore subject to Atex directive 2014/34/UE, is fundamental.