#Product Trends

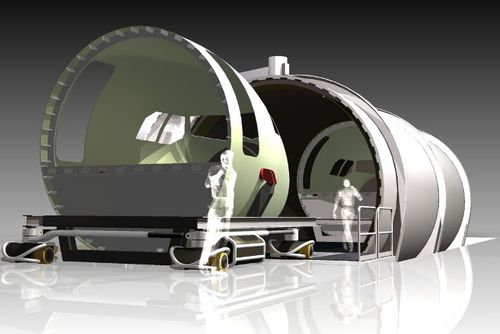

20T-jet engine transporter with mating technology

Efficient and fast mating of jet-engines to pylons

Seaqx designed and delivered an omni-directional transporter to a UK based jet-engine-manufacturer. This transporter is used to move the jet engine and to mate it in a test-cell to a pylon.

Thank to the mating technology, the jet engine can be lifted and tilted in all directions with a positioning accuracy of less than 0.5mm. The operator has instant feed-back from the position of the jet engine on the display of the radio remote control.

The largest engines which are used on the B787, A380 and A350 are manipulated with this transporter with 6D-deck.

With this solution, the customer does reduce mating time of a jet engine to a pylon considerably.

The driving technology is based on the Seaqx ultra-flat traction drives. This technology has allowed Seaqx to limit the building height to 500mm. To accommodate the different support cradles of the engines, the load deck is 5.5m long and 3.2m wide. The transporter can reach a velocity of 20m/min.

Potential other applications : mating train parts, fuselage parts, wind turbine parts