#Industry News

SECO/WARWICK FINDS THE WAY TO COMPLETE SUCCESSFUL PROJECTS IN BRAZIL

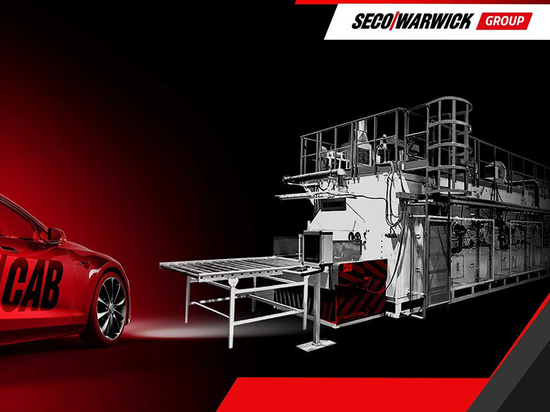

Commercial heat treater Nitrion do Brasil – the largest nitriding service provider in the region – has purchased another SECO/WARWICK Vector vacuum furnace.

The solution will operate in a new production hall and will handle their increasing order volume. Nitrion do Brasil is another commercial heat treater from South America that has chosen SECO/WARWICK’s solutions. This latest project is the result of the excellent synergy with the Group’s strategic partner in the region – Combustol.

SECO/WARWICK can dance the business samba

In Brazil, commercial heat treaters are particularly fond of Vector single-chamber vacuum furnaces. This line of furnaces was used by Supertrat, who wanted to improve and increase their hardening process power and boost the process economics. Dynamic sales growth and good forecasts on this market are the result of close cooperation between SECO/WARWICK and strategic partner – Combustol.

“Combustol supports SECO/WARWICK not only in sales, but also in service activities and the supply of spare parts. Such a partner in such a remote location is a huge advantage, helping us to beat the competition. In the case of cooperation with Nitrion de Brasil, another factor determined the success. The customer bought a furnace that we could deliver quickly,” said Maciej Korecki, Vice-President of the Vacuum Furnaces Segment in the SECO/WARWICK Group.

Vector – a vacuum furnace for many needs

The Vector vacuum furnace on order will solve Nitrion do Brasil’s problem of hardening larger elements, because the furnace is equipped with a large working space. This will affect the process economics (energy savings and the graphite chamber’s increased efficiency) as well as the process cleanliness and speed. The furnace is equipped with convection heating – a system which improves the heat transfer efficiency when heating at lower temperatures, as well as directional cooling, which allows the system to efficiently cool parts with problematic shapes in various ways.

“We were looking for a solution which would help not only increase our metal processing capabilities, but also efficiency and effectiveness. Vector is the first choice furnace and will operate in a completely new production hall. We know that it works in many commercial heat treating plants in Brazil, and works perfectly everywhere in the country. The fact that SECO/WARWICK cooperates with a Brazilian company operating locally is important,” says Peter Lutz, President of Nitrion do Brasil.

Commercial heat treaters are one of the SECO/WARWICK Group’s main partners. Every day, commercial heat treaters deal with many types of materials, a wide range of processes and technologies. What all customers in this industry have in common is the key parameter- operational efficiency, i.e. short production cycles and low production costs.

“We know the South American market; we have supplied vacuum furnaces to the largest commercial heat treating plants on this continent. Again, we executed the fastest vacuum furnace delivery on the Brazilian market.” – adds Łukasz Chwiałkowski, Sales Manager, SECO/WARWICK.