#Industry News

During the last 20 years, Sensofar built a tradition of excellence by providing solutions across a variety of industries and scientific fields. We continue to work closely with our customers to identify and develop solutions that meet unique and dema

At GPAINNOVA, the S neox Five Axis is specially used to quantify the polishing process quality and to report the roughness reduction in the samples after polishing with DLyte

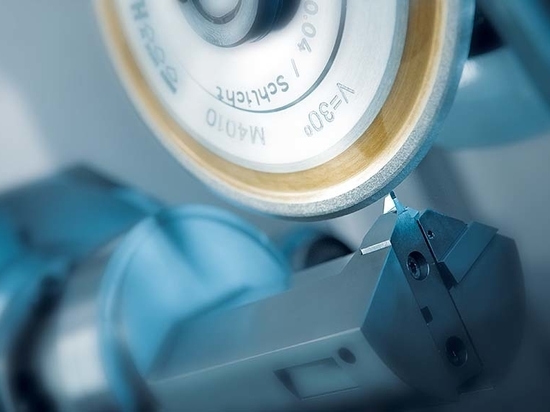

GPAINNOVA is reinventing the way manufacturing teams can produce high-quality metal surfacing. The DLyte series machines are based on patented Drylyte technology: the first dry electropolishing process that provides a solution for surface finishing of metal alloys for the industry. The applications range from grinding, rounding, and deburring to surface smoothing and high floss polishing of aesthetic parts. Sensofar’s S neox Five Axis allows us to obtain the highest-quality results in our current surface finishing solutions.

At GPAINNOVA, the Sensofar S neox Five Axis is used especially to quantify the quality of the polishing process and to report the roughness reduction in the samples after polishing with DLyte. Samples may vary from very rough additive manufacturing parts to mirror-like surfaces, all of them measurable with the Sensofar system thanks to its versatility of technologies, including Focus Variation, Confocal, and Interferometry techniques.

Below is a small example of what DLyte is capable of. A femoral component made of CoCr before and after DLyte polishing can be seen.

Before having the Sensofar system, a contact stylus profilometer was used, obtaining only profile parameters (Ra, Rz, Rq, etc). Even though Ra is the most used parameter, it does not provide any information on the spatial structure of the surface. Nonetheless, from now on, and thanks to Sensofar metrology, the surface parameters such as Sa —which is the extension of Ra to a surface— can be measured. Sa takes into account the surface of the sample to measure its roughness, allowing for a better characterization of the surfaces than Ra. The main advantage of measuring an area is the possibility to scan a larger area and to generate a surface of several millimeters in size as a better overview of the sample and thus get more reliable values. The 3D areal surface parameters are calculated following the ISO 25178 standard —considered as first and foremost the redefinition of the foundations of surface texture— and comprise the following parameters: Sa, Sq, Ssk, Sku, Sp, Sv, and Sz.

Read the full article on our website >