#Product Trends

Concentration & density measurement, phase detection and reaction monitoring with LiquiSonic®

Using the LiquiSonic® analyzers, quality and process safety are guaranteed as well as increased product yield and resource efficiency by savings in laboratory analysis and reducing the consumption of raw material and energy. The LiquiSonic® technology is based on the high-precision sonic velocity measurement that enables the determination of reliable and within seconds updated concentration values.

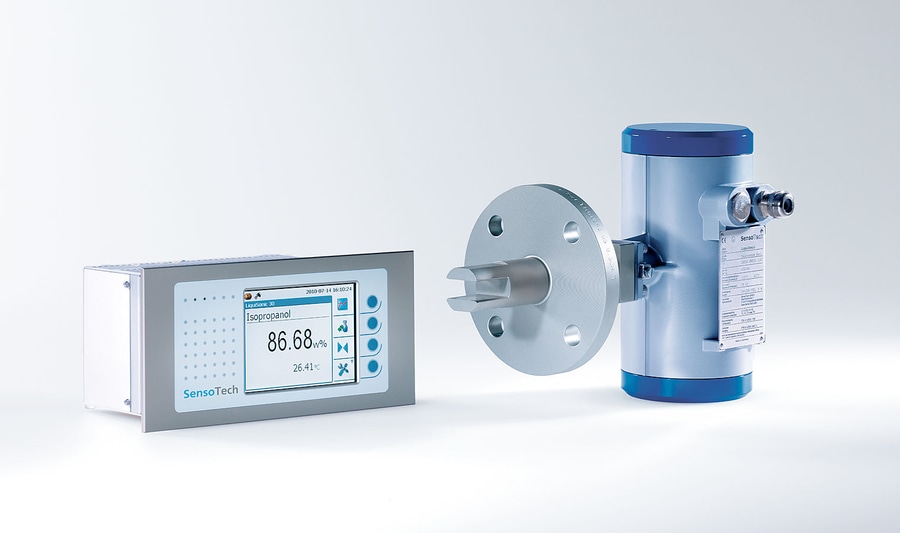

LiquiSonic® is made in Germany and consists of one controller and one or several sensors. The sensors are installed directly, without bypass, in the pipeline and are maintenance-free with long lifetime. The sensors are of stainless steel or for using in chemically aggressive liquids there are special sensor materials available. SensoTech is also flexible in providing different sensor lengths, process fittings and electronic housings. Requiring neither gaskets nor moving parts or “windows” to the process, the completely enclosed sensor design, makes the sensors extremely robust. For hazardous areas, there are LiquiSonic® sensors with ATEX & IECEx certification available. For the food or pharmaceutical industry, SensoTech manufactures high-hygienic sensors with an aseptic design including 3A approval.

The LiquiSonic® controller visualizes and saves the reproducible measuring data. By network integration the data can be analyzed via the personal PC. The controller can also be connected to control systems via 4-20 mA signals, digital outputs, Ethernet or fieldbus (e.g. Profibus DP), in order to control the process automatically.