#Industry News

New manual testing device for RAPID free-fall metal separators from Sesotec

Simple, convenient and safe function test

Schönberg, August 2024

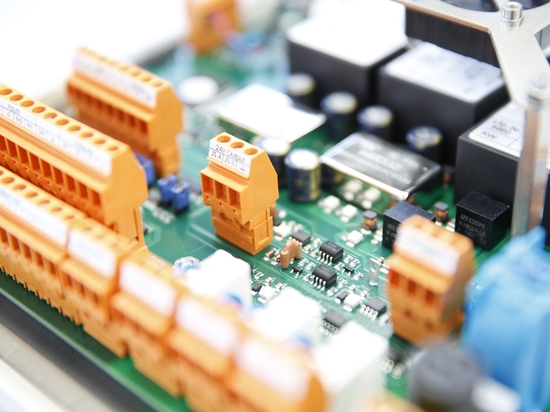

Sesotec, a leading supplier of equipment and systems for contaminant detection and material sorting, presents its latest development: the manual inline test device Freefall XS for RAPID and RAPID PRO SENSE metal separators. This innovation optimizes the testing process in the food industry and simplifies the functional testing of metal separators installed in free-fall conveyor lines.

The testing device offers IFS-compliant testing directly in the middle of the product flow. Specific configurations are available for use in ATEX environments, ensuring compliance with all relevant safety regulations. Combined with the automatic test function, food manufacturers and processors get maximum safety and maximum compliance.

Efficient testing

The functionality of the new testing device is simple and effective: a test specimen is manually inserted into the conveyor line directly upstream of the metal separator. It passes through the search coil inside the metal separator, is separated from the bulk material via a flap and can then be removed via a collecting grid.

Compact, hygienic design

The new testing device is characterized by a 100 mm shorter installation length compared to previous manual testing devices (75 mm shorter for diameters 200 mm and 250 mm), which facilitates its integration into existing systems. The removable insertion nozzle, which brings the test body into the middle of the product flow, and a retractable collecting grid for the test enable easy maintenance and cleaning.

Versatile in use

The appliance is suitable for various bulk materials, including powder, fine-grained material and granulates with a maximum grain size of ø < 8 mm. During production, the device can be used without a collecting grid, which ensures continuous operation.

Thomas Hellgermann, Product Manager Food at Sesotec, says: “With the manual testing device, routine performance testing is greatly simplified and the central insertion of test pieces directly into the product stream ensures precise and efficient functional testing of metal separators. We are convinced that this manual combination with the automatic testing device will help to raise food safety to a new level.”