#Industry News

Types of X-ray Tubes and High Voltage Power Supplies

Application Specification

Types of X-ray tubes and high voltage power supplies

X-ray tubes come in a variety of shapes and sizes to suit different applications, and a variety of high-voltage power supplies and control circuits are available. This section describes various types of X-ray tubes and three types of high-voltage circuits: Simple X-ray tube, X-ray tube with Be window, rotating anode X-ray tube, ceramic X-ray tube, end-window X-ray tube, X-ray tube for X-ray diffractometer, micro-focus X-ray tube, open X-ray tube (transmission target X-ray tube and reflection target X-ray tube). Three types of high-voltage circuits will be discussed: anode grounded, cathode grounded, and bipolar.

Simple X-ray tube

A simple X-ray tube, consisting of a filament (cathode) that produces hot electrons and an anode that produces X-rays when electrons collide, is fixed in a glass tube and vacuumed. Many of these tubes are relatively small and use voltages ranging from 20 kV to 130 kV. They are used for non-destructive testing using X-rays, foreign body detection, analysis and medical applications. They are usually placed in special metal housings (X-ray tube housings) filled with insulating oil to reduce X-ray leakage and make them safe and easy to handle. In some cases, the surface is covered with resin or other materials. In non-destructive testing of infrastructure, etc., X-ray shielding boxes filled with insulating gas are used instead of insulating oil to reduce the weight of X-ray devices.

Beryllium window X-ray tube

A beryllium window X-ray tube is an X-ray tube with beryllium attached to the output part of the X-ray (element symbol Be, atomic number 4). X-ray tubes range in voltage from a few thousand volts to 80kV and are mainly used for X-ray analysis.

Rotating anode X-ray tube

A rotating anode X-ray tube is a type of X-ray tube in which the anode that produces X-rays rotates when struck by an electron beam. By rotating the anode, the heat can be dispersed, increasing the tube current to increase the intensity of the X-rays. It is mainly used in medical applications such as CT and X-ray. Due to its complex structure, it is a very expensive X-ray tube.

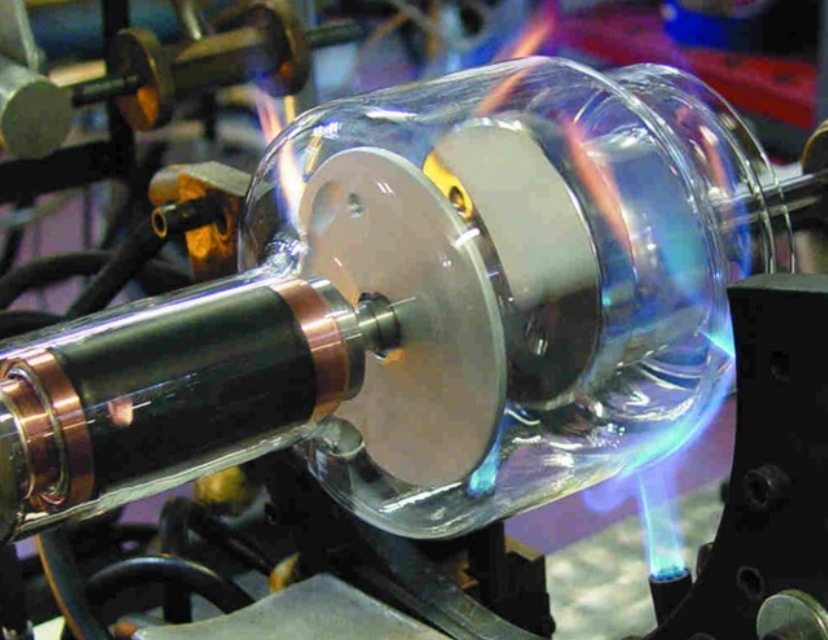

Ceramic X-ray tube

A ceramic X-ray tube is a vacuum tube in which the insulating part of the X-ray tube is made of ceramic instead of glass. They are heat and impact resistant and are mainly used for non-destructive testing and XRD. Other small X-ray tubes made of ceramics are also used in handheld X-ray fluorescence analyzers and soft X-ray ionization tubes.

End-window X-ray tube

An end-window X-ray tube is an X-ray tube with a beryllium window located at the end of the X-ray tube. Since the X-ray producing anode is located near the end of the beryllium window, the distance to the analyzed sample can be shortened and more X-rays can be emitted. The power supply for the X-ray tube is a high voltage supply with a grounded cathode, and the tube voltage is from 50 kV to 80 kV, and the power is from 50 W to 4 kW.

X-ray diffractometer (XRD X-ray Tubes)

X-ray tubes for XRD are X-ray tubes for X-ray diffractometry (XRD), and their designs are easily interchangeable because different target materials are used depending on the analytical target. X-ray tubes for XRD are sold by several companies and are highly interchangeable and can be used by different manufacturers. However, it is important to note that there are two types: short and long anodes. There are also glass and ceramic tube types on the market. The voltage can be up to 60kV, but the X-ray tube power is large, ranging from 1kW to 4kW, and requires water cooling. X-ray tubes used for XRD are anode-grounded.

Microfocus X-ray tube

Microfocus X-ray tube is a kind of X-ray tube with a very small X-ray emission area, ranging from a few microns to tens of microns. In a microfocus X-ray tube, electrons produced by the filament converge and strike the anode (target) to produce X-rays. The area where X-rays are produced is called the focus, and by narrowing the focus down to the micron scale, a clear and almost blurry X-ray image can be obtained even when the X-ray image is enlarged. For this purpose, microfocus X-ray tubes are used for nondestructive testing of electronic devices with fine structures.

Microfocusing X-ray tubes require multiple electrodes as well as a high-voltage power source for acceleration to focus the electrons. Use an acceleration voltage of 90kV to 150kV. There are two types of microfocus X-ray tubes: open X-ray tubes and sealed microfocus X-ray tubes.

Open X-ray tube (transmission target X-ray tube and reflection target X-ray tube)

An open X-ray tube is a type of X-ray tube with a replaceable filament and target. A vacuum pump is used to vacuum the inside of the X-ray tube to create a vacuum. Most open X-ray tubes have focal diameters of microfocus or nanofocus size, which allows them to capture images of small parts with minimal blurring even when zoomed in. There are two types of open X-ray tubes: transmission target type and reflection target type. The reflective target type uses X-rays produced on the incident side of the electron, just like a regular X-ray tube. On the other hand, transmission target-type open microfocus X-ray tubes use target materials, such as tungsten deposited on beryllium or diamond Windows. When an electron strikes a tungsten target, X-rays are emitted in all directions at 360 degrees. In a reflective X-ray tube, the X-rays emitted on the back of the target are very small due to the thickness of the target. In the transmission target X-ray tube, the tungsten target is very thin, and the substrate (window material) is beryllium or diamond, so many X-rays are emitted from the back. The transmission target-type microfocus X-ray tube uses these X-rays. Using a transmission target, the distance between the X-ray focus (the point of X-ray generation) and the sample can be made very short, allowing for large magnification. However, due to the heat capacity of the target, the target current cannot be increased. Open X-ray tubes are commercially available with an accelerated voltage range of 100 kV to 300 kV. In the transmission target X-ray tube, the tungsten target is very thin, and the substrate (window material) is beryllium or diamond, so many X-rays are emitted from the back. The transmission target-type microfocus X-ray tube uses these X-rays. Using a transmission target, the distance between the X-ray focus (the point of X-ray generation) and the sample can be made very short, allowing for large magnification. However, due to the heat capacity of the target, the target current cannot be increased. Open X-ray tubes are commercially available with an accelerated voltage range of 100 kV to 300 kV. In the transmission target X-ray tube, the tungsten target is very thin, and the substrate (window material) is beryllium or diamond, so many X-rays are emitted from the back. The transmission target-type microfocus X-ray tube uses these X-rays. Using a transmission target, the distance between the X-ray focus (the point of X-ray generation) and the sample can be made very short, allowing for large magnification. However, due to the heat capacity of the target, the target current cannot be increased. Open X-ray tubes are commercially available with an accelerated voltage range of 100 kV to 300 kV. Using a transmission target, the distance between the X-ray focus (the point of X-ray generation) and the sample can be made very short, allowing for large magnification. However, due to the heat capacity of the target, the target current cannot be increased. Open X-ray tubes are commercially available with an accelerated voltage range of 100 kV to 300 kV. Using a transmission target, the distance between the X-ray focus (the point of X-ray generation) and the sample can be made very short, allowing for large magnification. However, due to the heat capacity of the target, the target current cannot be increased. Open X-ray tubes are commercially available with an accelerated voltage range of 100 kV to 300 kV.

Three kinds of high-voltage circuits

Anode ground connection

Anode grounding is an easy way to dissipate heat because the anode of an X-ray tube that generates a lot of heat can be grounded. As for the power supply, a high voltage power supply with a negative output is connected to the cathode side, but a power supply for the filament floating above that potential is also required. This connection mode is suitable for X-ray tubes for XRD, open micro-focus X-ray tubes, ceramic X-ray tubes, etc.

Cathode ground connection

In a cathode-ground connection, a filament of the X-ray tube is connected to the ground potential, and a positive output high-voltage power supply is connected to the anode side. The current of the X-ray tube is controlled by the power of the filament. This connection is suitable for sealed microfocus X-ray tubes and end-window XRF X-ray tubes. For high-power XRF X-ray tubes, water cooling with pure water is used to cool the anode.

Bipolar connection

In a bipolar connection, the negative output high voltage power supply is connected to the cathode of the X-ray tube and the positive output high voltage power supply is connected to the anode. This connection is used when the acceleration voltage (tube voltage) of the X-rays needs to be increased. For example, if a 320kV tube voltage is required, connect the -160kV high-voltage power supply to the cathode side and the +160kV power supply to the anode side.

Wisman has a range of power supplies that can be used for X-ray tubes. Example: XNA; XRD; XRA; XRW;

Application field: X-ray fluorimeter, X-ray point machine, X-ray level measurement, X-ray level detection, thickness gauge, antique identification, aluminum strip thickness measurement, aluminum plate thickness measurement, paper, film, aluminum foil thickness measurement, Online elemental Analysis, X-ray fluoroscopy, particle size testing, density measurement, paper composition testing, online process control, ROHS testing, thickness measurement, printed circuit board inspection system, X-ray fluorescence analysis, Radiographic field, X-ray imaging, multi-layer PCB alignment, particle size detection, density measurement, process control, X-ray spectroscopy, Welding head, wire head detection, etc.