#Industry News

The perfect integration of the drive shaft industry and balancing machines

drive shaft industry balancing machines

In modern industrial production, precision and efficiency are important criteria for measuring the quality of a product or equipment. This is particularly important for the driveshaft industry. As an important part of automobiles, mechanical equipment, etc., the quality of transmission shafts directly affects the operating efficiency and safety of the entire equipment. Therefore, how to improve the manufacturing accuracy and production efficiency of drive shafts has become an important challenge facing the drive shaft industry. The balancing machine plays an important role in this process.

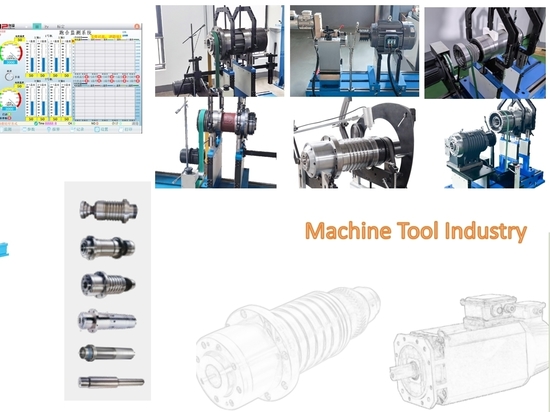

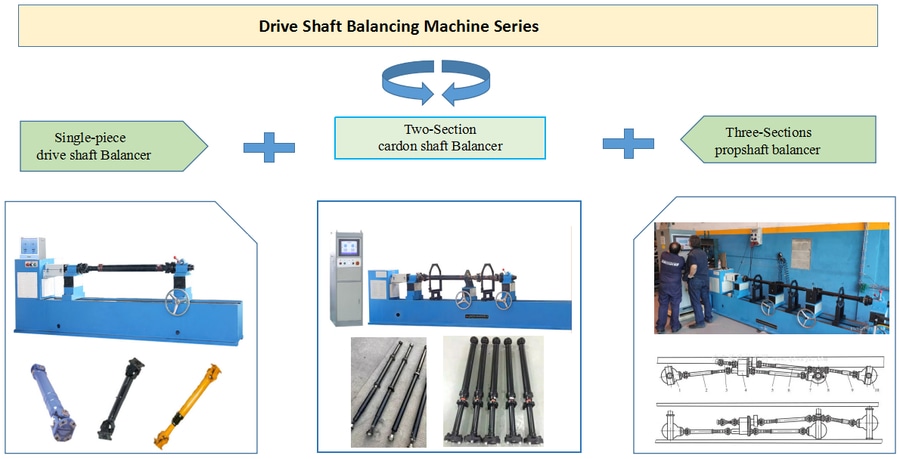

A balancing machine is a device specially used to detect and adjust the imbalance of rotating objects. By accurately measuring and adjusting the imbalance of the object, it can reach a predetermined balance state. In the drive shaft industry, balancing machines are widely used in the production and testing of drive shafts

First, the balancing machine can improve the manufacturing accuracy of the drive shaft. During the production process of drive shafts, various imbalances may occur due to factors such as materials and processes. This imbalance will not only affect the operating efficiency of the drive shaft, but may also cause damage to the equipment. By using a balancing machine, the balance state of the drive shaft can be detected and adjusted in real time during the production process, thereby greatly improving the manufacturing accuracy of the drive shaft.

Secondly, the balancing machine can improve the production efficiency of the drive shaft. The traditional transmission shaft inspection method requires manual operation, which is time-consuming and labor-intensive. The balancing machine can automatically complete the detection and adjustment process, greatly improving production efficiency. At the same time, by using a balancing machine, equipment failures caused by unbalanced transmission shafts can also be reduced, thereby reducing production costs.

Finally, the balancing machine can ensure the quality stability of the drive shaft. Due to the high precision and high efficiency of the balancing machine, the transmission shafts produced every time can meet the same quality standards, ensuring the stability of product quality. This is of great significance for improving brand reputation and expanding market share.

In general, the application of balancing machines in the transmission shaft industry can not only improve product quality and production efficiency, but also ensure the stability of product quality. With the continuous advancement of science and technology, we believe that the application of balancing machines in the transmission shaft industry will become more and more extensive and make greater contributions to the development of the transmission shaft industry.