#Industry News

How to choose the clutch balancing machine that suits you

How to choose the clutch balancing machine that suits you

In automobile manufacturing, the unbalance of rotating parts such as clutch pressure plate, clutch drum, clutch cover and clutch assembly will affect its performance and life, so more and more manufacturers are conducting more and more strict control of the balancing process requirements.

What is an automatic balancing machine? What benefits can the automatic balancing machine bring to the manufacturer?

Balancing machine is a kind of equipment used to measure and correct the unbalance of rotating parts, the main working principle is to determine the unbalanced position and amount of the rotating parts by measuring the vibration or centrifugal force, and then remove or add the material in a specific position by drilling, riveting or milling to eliminate or reduce the unbalance.

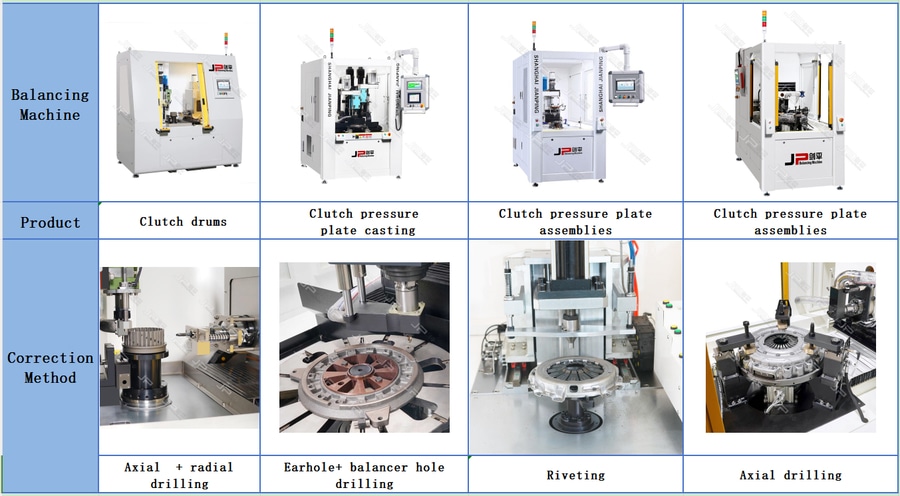

For the balancing process requirements of most clutch manufacturers for various clutch components, JP has the following equipment to meet different customer choices:

1.Automatic drilling balancing machine: applied to the automatic unbalance correction of clutch drum and clutch assembly, can meet the customer's axial and radial unbalance weight removal requirements.

2.Automatic milling balancing machine: suitable for clutch assembly and clutch cover, mainly meets the process requirements of customer milling and weight removal.

3.Automatic riveting & pressing balancing machine: suitable for clutch cover and clutch assembly, by pressurizing and riveting the counterweight block in the specified position to achieve the effect of unbalance correction.

4.Automatic ear hole drilling + automatic drilling balancing machine, suitable for clutch pressure plate, first to drill the ear hole and then balance, one equipment can solve customer's two processes, more cost-saving and efficient.

For above machine models, customers can independently choose their own balancing machine according to their own process to ensure the quality of the produced clutch, improve the manufacturing level of the process, increase output, improve efficiency, and reduce production costs.

If your clutch also needs to be balanced, welcome to send us an inquiry!