#Industry News

Why does the clutch need dynamic balancing test?

Why does the clutch need dynamic balancing test?

Why does the clutch need dynamic balancing test?

1.Reduce vibration: Dynamic balancing test ensures that the centrifugal force generated by the clutch components during high-speed rotation is balanced, thus significantly reducing vibration levels.

2.Extend the service life: Through dynamic balancing treatment, the unnecessary wear of the clutch system can be reduced and its service life can be extended.

3.Improve safety: unbalanced clutch may lead to control difficulties and increase driving safety hazards; Proper dynamic unbalance correction can avoid such problems.

4.Improve performance: A well-balanced clutch can transmit power more smoothly, improving the overall performance and driving experience of the car.

5.Reduce noise: unbalanced parts may produce excessive noise when rotating, and the noise level can be effectively reduced through dynamic balance testing.

How to check if the clutch is balanced?

The commonly used method in modern production and maintenance is to carry out data acquisition through the clutch special dynamic balancing machine, which can not only find the unbalanced position and the amount of the unbalance, but also adjust the the unbalance amount to achieve a better state. This way of unbalance adjustment can usually use the way of adding weight and the way of removing weight. The former is to perform (riveting & pressing) treatment by using a small amount of rivets, and the latter is to remove the excessive weight by using the corresponding tool (remove weight by milling/drilling ).

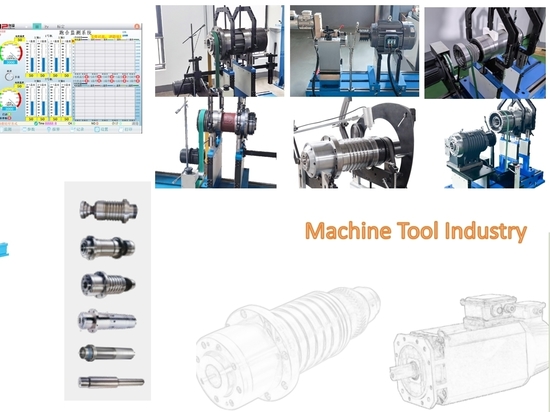

JP has developed balancing machines of three correction types for clutch unbalance correction, if you want to improve your production efficiency and product quality welcome to consult