#Product Trends

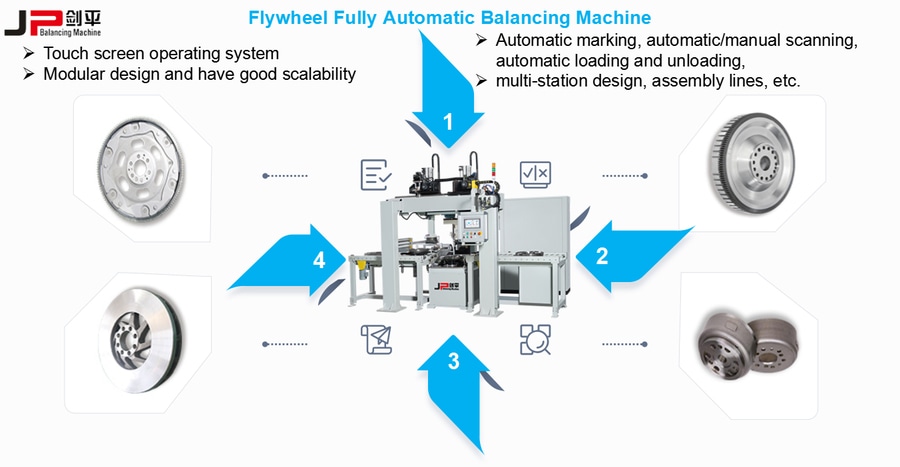

Shanghai Jianping -- Flywheel automatic balancing machine

Shanghai Jianping -- Flywheel automatic balancing machine

The flywheel belongs to the automobile flywheel, one of the engine components, which is the inertial device that keeps the piston in the engine moving. The flywheel is a large disc of energy storage, fixed to the transmission components, and rotates with the power output of the crankshaft

Today, we specially introduce our 3-station flywheel automatic balancing machine.

W3LZ1-150 automatic balancing machine is used for the workpiece dynamic unbalance test and automatic drilling & weight removal. The measurement control system integrates measurement, control, calculation and other functions in one, with automatic measurement and positioning functions. The front and back-end system composed of a measurement control unit and an industrial PLC, can measure the amount and the angular position of the unbalance.

Product characteristics

1. Continuous production cycle time, efficient and rhythmic operation;

2. Human machine exchange interface, with touch screen, easy operation;

3. Rigid structure design, high service life;

4. Can integrate with the production line to provide automatic production;

5. Stable performance, low error rate;

Product process:

1.Loading: The workpiece flows through the loading conveyor to the loading position;

2.Handling: The truss manipulator grabs the workpiece to the measuring station;

3.Initial test: After the fixture clamps the workpiece, the balancing machine drives the workpiece to accelerate to the set speed and rotate for unbalance measurement ;

4.Auto-positioning&weight removal: After the measurement is over, it automatically locates to the weight removal position, the force offset unit prevents the workpiece from moving during the weight removal, the drilling unit moves to the weight removal position, to drill the designated position of the workpiece, after it completes, the drilling unit and the force offset unit reset;

5.Retest: The balancing machine automatically starts to retest the workpiece after weight removal according to the reset signal of the sensor.

6.Result display: If the workpiece is qualified, the green indicator light is on and the touch screen shows OK; if the workpiece is unqualified, the red indicator light is on and the touch screen shows NG;

7.Unloading: The truss manipulator grabs the workpiece to the unloading conveyor;

8.Sorting: When the workpiece is a NG product, the sorting unit works, and the workpiece automatically slides into the NG conveyor;

Why choose JP Flywheel Automatic Balancing Machine

Flexible flywheel is one of the key parts of automatic transmission, which needs to be balanced dynamically in the production process. For flexible flywheel such thin sheet parts, the more suitable way to remove weight is drilling. Shanghai Jianping researched on the drilling automatic balancing technology of flexible flywheel, analyzed the operation process of the equipment, designed the measurement unit, automatic clamping unit and drill unit and other core mechanical components, selected the measurement and control hardware, wrote each software module, and summed up the requirements of drilling weight removal algorithm. A 3-station flywheel automatic balancing machine was made and its performance was tested and the production site running was carried out in Russia. The results show that the measurement flipping deviation, drilling residual amount and production cycle time of the developed 3-station flywheel automatic balancing machine meet the technological requirements, and won the unanimous praise of our customer.

JP Flywheel automatic balancing machine · Making flywheel more balanced