#Industry News

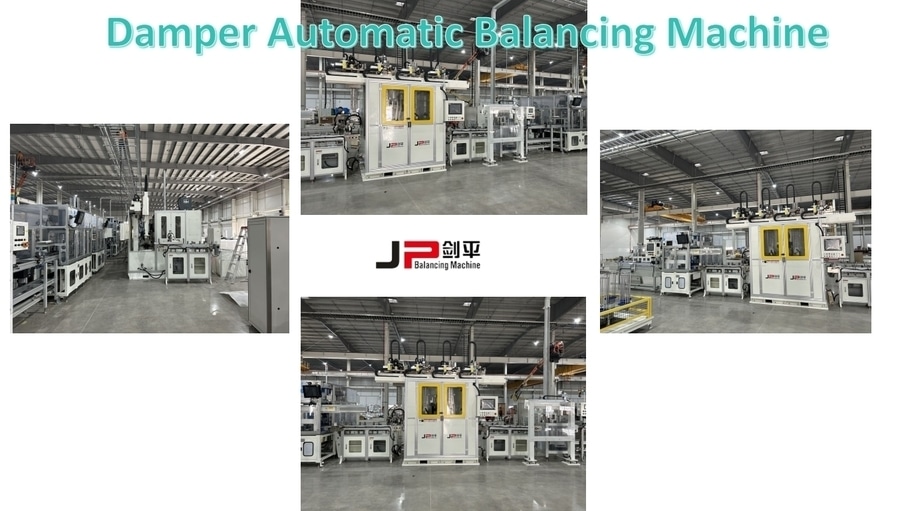

Congratulations on the successful operation of the five-station shock absorber automatic balancing machine in Mexico

Congratulations on the successful operation of the five-station shock absorber automatic balancing machine in Mexico

Damper, is used to suppress the shock and the impact from the road surface when the spring rebounds after absorbing the shock. It is widely used in automobiles to accelerate the attenuation of frame and body vibration to improve the ride comfort of automobiles. If the shock absorber is broken and not replaced, it will reduce the shock absorption effect of the vehicle, resulting in the shock amplitude of the vehicle being too fast or too large, especially when the vehicle passes through a bumpy section, the impact speed is more obvious, affecting the grip of the tire and affecting driving safety

JP shock absorber automatic balancing machine came into being. Flexible and versatile machine design concepts are applied, ranging from fully automatic single-station measurement and correction integrated models to fully automatic five-station models, the number of stations depends on the specific cycle time and the design concept of the selected model.

The unbalance correction usually adopts the axial drilling method. There are also axial milling & grinding methods on the workpiece cover plate. It can be fed manually or automatically by a manipulator or robot with a transfer device.

W5LZ1 is a special dynamic balancing machine for differential case, which is mainly composed of 2 test balancing machines, 1 drill unit, safety cover, loading and unloading conveyor, electric cabinet, vacuum cleaner and so on.

Product unbalance measurement, conveying between stations, drilling correction, workpiece loading and unloading are automatically completed by the equipment;

The production cycle time is fast, and the deceleration ratio is high;

Strong structural rigidity;

15" large HMI touch screen operation;

Measurement and weight removal data can be exported in CSV format or uploaded via MES (optional function);

Software difference: Function display of the whole machine: whether it works, whether it is qualified, counting function;

PLC: Provide remote guidance, maintenance;

Safety Settings: Equipment safety door with interlock design, Two hands start button, safe and reliable, protect the personal safety of operators to the greatest extent ;

Can be integrated with the production line to achieve automated production;

Highlights

Wide compatibility

Short cycle

Fast changeover

High balance accuracy

High working efficiency, can achieve mass production

Intelligent - robot/conveyor handling

Data exchange and uploading are also possible

Customized according to customer requirements

We focus on "balancing", and we are a professional and dedicated manufacturer.

Founded in 2004, Shanghai Jianping Dynamic Balancing Machine Manufacturing Co., Ltd. has ushered in its 20th anniversary in 2024.

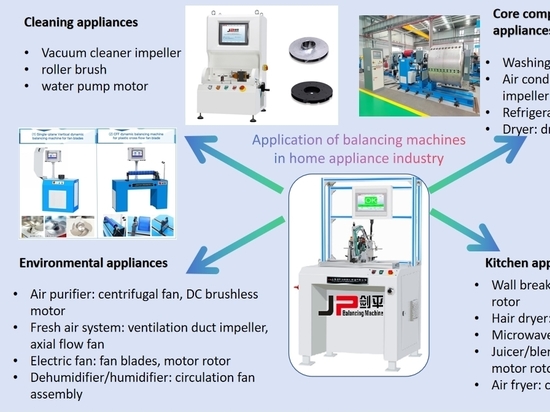

Over the past 20 years, we have been developing and manufacturing "Balance testing instruments" and "Balancing correction machines" for measuring and correcting the unbalance of the motor rotating parts (armatures) used in automobiles, household appliances and power tools.

We have won the trust of many customers through careful customization to meet their needs.

Based on our success in China, we are also expanding overseas business, including setting up distributors in Spain, Thailand, USA, Russia, Korea, Mexico, Chile, etc., to provide local support.

We will continue to respond to customer challenges and detailed requirements that other companies cannot meet.

We will contribute to the production of customers with advanced technical capabilities and valuable suggestions, welcome to choose us.