#Product Trends

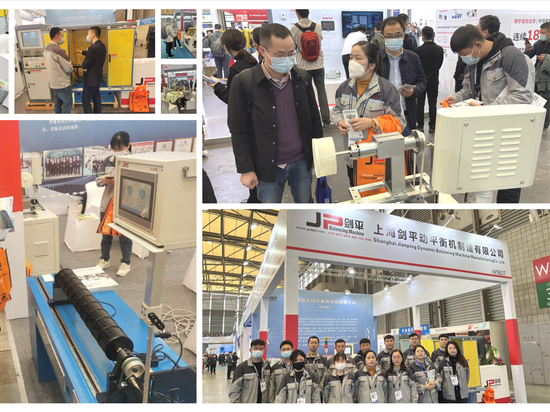

Machine tool spindle dynamic balancing machine

Machine tool spindle dynamic balancing machine

In the field of precision machining, the dynamic balance of the machine tool spindle is very important to improve the performance of the equipment and extend the service life. Our dynamic balancing machines and spindle running-in tables are ideal for optimizing machine performance and ensuring productivity.

JP spindle balancing machine

-- Our dynamic balancing machine adopts advanced Jianping electronic measurement system to provide a variety of measurement methods,

-- Meet a variety of complex needs. Whether it is dynamic balancing or static balancing, we can cope with it easily.

- Up to 10 kinds of bearing mode can be flexibly customized according to customer needs to ensure that every measurement is accurate.

-- Unique combination of multiple calibration coefficients, so that the system sensitivity automatically adjusted, shift without jumping, to ensure the stability of measurement.

- Software and hardware dual filtering and data compression technology, further improve the accuracy and reliability of measurement.

Through these technologies, our dynamic balancing machines are able to accurately measure the unbalance of the machine tool spindle for effective dynamic balancing correction. This not only improves the mass distribution of the spindle, but also significantly reduces vibration, improves equipment performance, and extends service life.

JP spindle running-in table: comprehensive monitoring to ensure stable operation

Complementary to the dynamic balancing machine is our spindle running-in table. It is specially designed for the running-in and condition monitoring of the spindle, especially for real-time monitoring of the temperature of each bearing. The variable frequency motor is used to drag the belt and drive the spindle to achieve multi-speed automatic running, and the speed and time of each section can be customized to meet the needs of different working conditions.

During the running-in process, our equipment can monitor the temperature of each sensor in real time and generate a temperature curve, so that you can understand the entire running process at a glance. Once the temperature is too high or the sensor is disconnected, the device will immediately alarm, and automatically reduce the speed or stop to ensure the safety of the equipment. In addition, the running-in record curve printing function, as well as the drive motor temperature monitoring and alarm function, provide you with comprehensive security.

Motor spindle balancing machine: Professional testing to ensure excellent performance

For motor spindles, we also offer specialized motor spindles balancing machines. By measuring the unbalanced state of the rotating shaft, the device can take corresponding measures to adjust the mass distribution of the shaft, so as to achieve the balance of the shaft. This can not only effectively reduce the vibration of the spindle and bearing, reduce the temperature rise of the spindle, but also significantly improve the service life of the spindle bearing.

For motor spindles, we also offer specialized motor spindles balancing machines. By measuring the unbalanced state of the rotating shaft, the device can take corresponding measures to adjust the mass distribution of the shaft, so as to achieve the balance of the shaft. This can not only effectively reduce the vibration of the spindle and bearing, reduce the temperature rise of the spindle, but also significantly improve the service life of the spindle bearing.