#Industry News

Exploring the Different Types of electronic grade silicone adhesive sealant and Their Applications

Best Electronic Grade Silicone Adhesive Sealant Adhesive Glue Manufacturer

In the dynamic and constantly evolving electronic field, the significance of materials that guarantee the resilience, efficiency, and endurance of devices cannot be emphasized enough. Among the indispensable materials in this industry is the electronic grade silicone adhesive sealant, which has proven to be a versatile compound with a multitude of applications. From sealing electronic components to providing thermal management in a wide range of devices, this remarkable substance is a crucial component in the world of electronics.

In this comprehensive blog post, we will delve into the fascinating world of electronic grade silicone adhesive sealants. We will explore the different types available in the market, their unique properties, and how they are utilized in various applications.

Explaining Composition of Electronic Grade Silicone Adhesive Sealant

Electronic grade silicone adhesive sealant is composed of silicone polymers, which are synthetic materials made up of repeating units of silicon and oxygen atoms. These polymers have unique chemical properties that make them ideal for use in the electronics industry. Silicone adhesive sealants are known for their excellent resistance to high temperatures, electrical insulation properties, and good adhesion to various substrates.

Compared to other types of adhesive sealants, electronic grade silicone adhesive sealant has several distinct advantages. It has a wide operating temperature range, ranging from -50°C to 200°C, making it suitable for use in both low and high-temperature environments. It also has excellent electrical insulation properties, which is crucial in preventing electrical leakage and short circuits in electronic devices. Additionally, silicone adhesive sealants have good adhesion to various substrates, including metals, plastics, and glass.

Types of Electronic Grade Silicone Adhesive Sealant

There are several types of electronic grade silicone adhesive sealants available in the market, each with its own unique properties and applications.

One-part silicone adhesive sealant is a ready-to-use product that does not require any mixing or curing process. It is typically supplied in a tube or cartridge and can be easily applied using a caulking gun or a dispensing tool. One-part silicone adhesive sealants are commonly used for bonding and sealing applications where a fast and convenient solution is required.

Two-part silicone adhesive sealant, on the other hand, consists of two components that need to be mixed together before application. These components, usually referred to as Part A and Part B, react with each other to form a cross-linked network, providing a strong and durable bond. Two-part silicone adhesive sealants are often used in applications that require a higher level of strength and durability.

UV-cured silicone adhesive sealant is a type of silicone adhesive sealant that cures when exposed to ultraviolet (UV) light. It is typically supplied as a liquid or gel and requires a UV light source for curing. UV-cured silicone adhesive sealants offer fast curing times and can be used in applications where rapid bonding and sealing are required.

High-temperature silicone adhesive sealant is specifically formulated to withstand extreme temperatures. It can withstand temperatures up to 300°C or higher, making it suitable for use in applications where high-temperature resistance is critical.

Applications of Electronic Grade Silicone Adhesive Sealant in Electronics Industry

Electronic grade silicone adhesive sealant has a wide range of applications in the electronics industry. It is commonly used for bonding and sealing electronic components, providing protection against moisture, dust, and other environmental factors, and managing thermal properties in electronic devices.

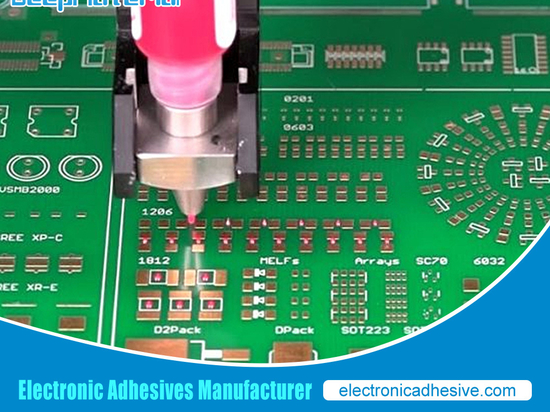

One of the main applications of electronic grade silicone adhesive sealant is the bonding and sealing of electronic components. It is used to bond components such as circuit boards, connectors, and sensors to ensure their proper functioning and reliability. Silicone adhesive sealants provide a strong and durable bond that can withstand the stresses and vibrations encountered in electronic devices.

In addition to bonding and sealing, electronic grade silicone adhesive sealant also provides protection against moisture, dust, and other environmental factors. Electronic devices are often exposed to harsh environments, such as high humidity or extreme temperatures, which can damage the internal components. Silicone adhesive sealants create a barrier that prevents moisture and dust from entering the device, ensuring its long-term durability and reliability.

Furthermore, electronic grade silicone adhesive sealant is used for thermal management in electronic devices. Electronic components generate heat during operation, and if not properly managed, this heat can lead to performance issues and premature failure. Silicone adhesive sealants with high thermal conductivity are used to transfer heat away from the components, ensuring optimal performance and longevity.

Benefits of Using Electronic Grade Silicone Adhesive Sealant

There are several benefits to using electronic grade silicone adhesive sealant in the electronics industry.

One of the main benefits is its high temperature resistance. Silicone adhesive sealants can withstand extreme temperatures, ranging from -50°C to 200°C or higher, without losing their properties. This makes them suitable for use in a wide range of applications, including those that require exposure to high temperatures.

Another benefit is the excellent electrical insulation properties of silicone adhesive sealants. They have a high dielectric strength, which means they can withstand high voltages without conducting electricity. This is crucial in preventing electrical leakage and short circuits in electronic devices.

Additionally, electronic grade silicone adhesive sealants have good adhesion to various substrates, including metals, plastics, and glass. This allows them to bond and seal different types of materials, providing a strong and durable bond.

Furthermore, silicone adhesive sealants are known for their long-term durability. They are resistant to aging, weathering, and UV radiation, ensuring that the bond remains intact and reliable over time.

Final Thoughts

In conclusion, the world of electronic grade silicone adhesive sealants is vast and varied. These sealants, with their unique properties and diverse applications, play a crucial role in the electronics industry. From thermal conductivity to electrical insulation, from high-temperature resistance to excellent adhesion, these sealants offer a range of benefits that make them indispensable in various electronic applications.

We have explored several types of electronic grade silicone adhesive sealants in this blog post. Each type has its own set of characteristics that make it suitable for specific applications.

For more about choosing the Different Types of electronic grade silicone adhesive sealant and Their Applications, you can pay a visit to DeepMaterial at https://www.electronicadhesive.com/about/ for more info.