#Industry News

Industrial Encryption Protocol for Industrial Grade Display Security

Industrial Encryption Protocol for Industrial Grade Display Security

One of the major advantages of industrial monitors is that they can adapt to harsh environments, and their various features, such as waterproof function and so on, are designed for harsh environments. With dustproof, waterproof (IP65/IP67), wide temperature (-30℃~70℃) and anti-vibration characteristics, industrial monitors can be widely used in manufacturing, energy, transportation and other scenes. Its high brightness (more than 1000 nits) screen can be clearly displayed in bright light, sunlight, outdoor and other environments. Its capacitive or resistive touch function supports glove or wet hand operation. For example, in a smart factory, the industrial display, as the core of HMI, can monitor the production line data in real time and issue control commands, and at the same time, it is compatible with PLC, SCADA and other systems, realizing the interconnection of equipment and remote operation and maintenance.

Technical Challenges and Reliability

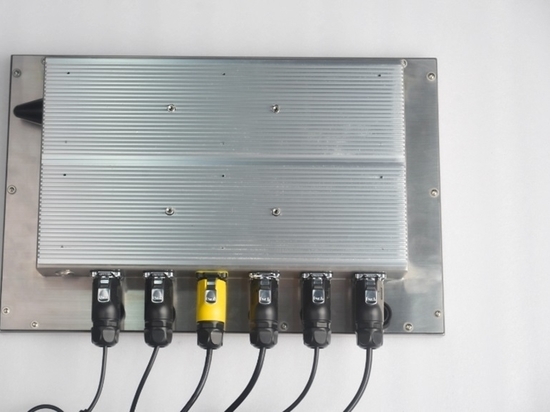

Industrial environment of high temperature and low temperature, outdoor environment, electromagnetic interference, dust and oil, mechanical impact on the monitor stability has a high challenge. However, industrial monitors also have their own solutions, such as the use of the outer frame to choose the metal shell to achieve shielding interference, the use of full lamination process to prevent dust into the air and dust, optical adhesive (OCA) to enhance the durability of touch. In addition, industrial-grade LCD panels (e.g., wide viewing angle, low power consumption) and a wide-voltage power supply design (9~36V DC) ensure that the device can still operate stably even under voltage fluctuations. Strict MTBF (Mean Time Between Failure) certifications (e.g. 50,000 hours) further guarantee long-term reliability.

Data Security and Communication Protocol Adaptation

Industrial displays involve data and so on, so data transmission needs to be secure, especially when connecting to the cloud or across networks. Mainstream solutions integrate encryption protocols such as TLS/SSL and OPC UA to prevent data theft or tampering. For example, AES-256 encryption is implemented through hardware encryption module, combined with X.509 certificate two-way authentication, only authorized devices can access the system. At the same time, it supports the security extension version of Modbus TCP, Profinet and other industrial protocols, taking into account real-time and confidentiality, to meet the demand for full-link protection of device-display-cloud platform in IIoT scenarios.

Future Development Trends

With the popularity of AI technology, industrial displays are evolving towards intelligence, for example, integrating edge computing capabilities to process data locally and reduce cloud load; carrying AI algorithms to realize various functions, and being able to warn or replace employees in visual quality inspection when equipment is abnormal. In the future, the improvement of Mini-LED backlight technology will screen to improve contrast and energy efficiency, but also allows flexible screens to adapt to irregular device panels. In addition, the integration of zero-trust architecture (continuous authentication) and 5G+TSN (time-sensitive network) further strengthens real-time control and security collaboration, and promotes the upgrade of Industry 4.0 in the directionof high reliability and adaptability.