#Industry News

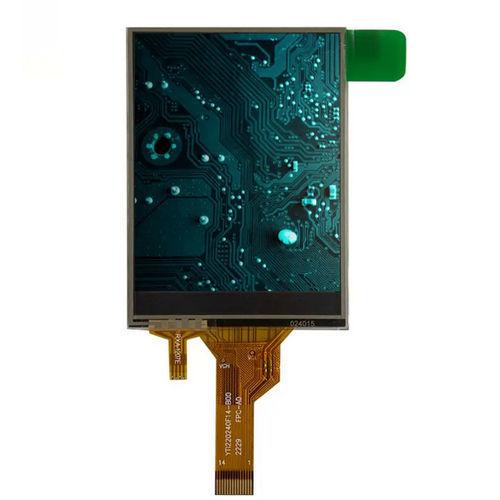

How to Test an LCD Display?

The back-end detection process is essential to ensure the LCD module functions correctly and meets the required specifications.

I. The back-end detection process of TFT LCD

The LCD Display back-end detection process involves testing the electrical and functional properties of the LCD module after it has been assembled.

This process is important to ensure the LCD display functions correctly and meets the required specifications.

The back-end detection process typically involves the following steps:

● Electrical testing

The electrical properties of the LCD module are tested using specialized equipment to measure parameters such as voltage, current, resistance, and capacitance.

This testing is done to ensure that the LCD module is functioning within the specified electrical parameters.

● Visual inspection

During this step, the LCD module is visually inspected to check for any physical defects that could affect the display quality.

Scratches, cracks, or other imperfections can impact the display quality and must be identified and addressed before the module is integrated into the final product.

● Functional testing

This step involves checking for any issues with the display, such as dead pixels, color accuracy, and brightness.

Specialized equipment is used to simulate real-world usage scenarios, such as displaying different colors and images to ensure that the display functions correctly and meets the required specifications.

● Environmental testing

It ensures that the LCD module can withstand various conditions such as temperature, humidity, and vibration.

Environmental testing is crucial because LCD modules are often used in harsh environments, and they must be able to function correctly under these conditions.

II. Conclusion

Overall, the back-end detection process is essential to ensure the LCD module functions correctly and meets the required specifications.

Each step of the process is carefully designed to identify any potential issues with the module and address them before it is integrated into the final product.

By following the back-end detection process, manufacturers can ensure that the LCD displays they produce are of high quality and meet the expectations of their customers.