#Industry News

What is a Resistive Touchscreen?

In the era of touchscreens, there are various technologies available to provide users with intuitive and interactive interfaces. Among these technologies, resistive touchscreens have played a significant role.

I. What is a Resistive Touchscreen?

In the era of touchscreens, there are various technologies available to provide users with intuitive and interactive interfaces. Among these technologies, resistive touchscreens have played a significant role. This blog post aims to delve into the details of resistive touchscreens, exploring their technology, working principles, advantages, and applications. By the end of this article, you will have a comprehensive understanding of resistive touchscreens and their diverse applications. Let’s get started!

● Overview

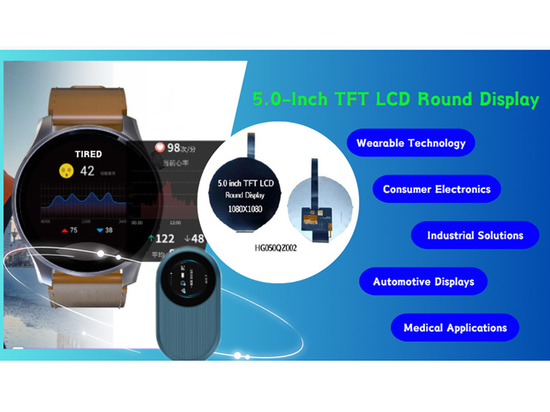

Resistive touchscreens are a popular type of touch-sensitive display technology that enables users to interact with devices by touching the screen. They are widely used in various industries, including consumer electronics, industrial automation, medical devices, and more.

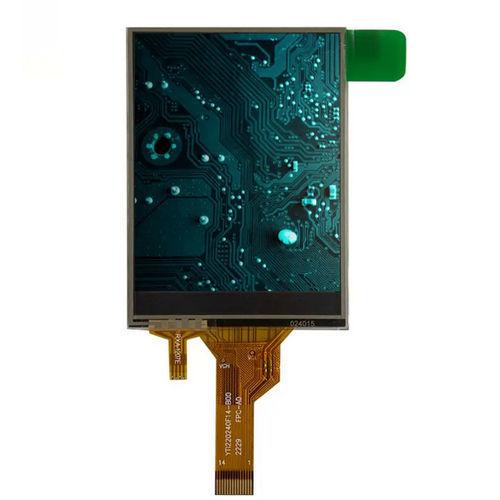

● Structure of resistive touchscreens

The structure of the resistive touch screen can be divided into the following parts

- Outer Layer:

Made of a flexible material like polyester or glass.

Transparent to allow visibility of the display content.

Provides the tactile surface for users to interact with.

- Inner Layer:

Composed of a rigid substrate.

Provides structural support and stability to the touchscreen.

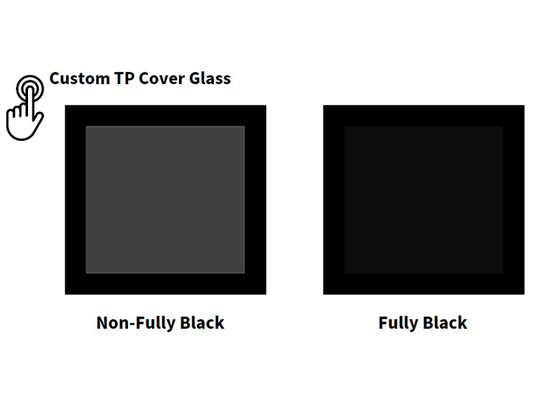

Transparent Conductive Layers:

Both the outer and inner layers are coated with a transparent conductive material, typically indium tin oxide (ITO).

These conductive layers allow for the flow of electrical current.

- Thin Gap:

Separates the two conductive layers.

When pressure is applied to the screen, the layers come into contact, completing an electrical circuit.

- Electrical Connectors:

Found at the edges of the touchscreen.

Connect the conductive layers to the touchscreen controller.

- Touchscreen Controller:

Detects changes in electrical resistance caused by touch input.

Calculates the precise touch coordinates based on the resistance values.

II. Working Principle of Resistive Touchscreens

● Layers and functionality

The resistive touchscreen operates on the principle of pressure detection. When pressure is applied to the screen, the top and bottom conductive layers come into contact, creating a closed circuit. This change in electrical resistance is detected by the touchscreen controller, which calculates the exact touch coordinates.

● Resistive touch sensing mechanism

The resistive touchscreen utilizes a voltage divider network to determine the touch position accurately. The controller applies a voltage across the top layer and measures the voltage at different points along the bottom layer. By analyzing the changes in voltage, the controller determines the touch location based on the ratio of resistance values.

III. Advantages of Resistive Touchscreens

● Accuracy and precision

Resistive touchscreens offer high accuracy and precision, allowing for precise touch input recognition. They can detect touch input with a stylus, gloved hands, or any object, making them versatile for various user scenarios.

● Durability and reliability

Resistive touchscreens are known for their durability and reliability. The absence of complex electronics in the touchscreen layers makes them less prone to failure due to environmental factors such as temperature, humidity, or electromagnetic interference.

● Versatility and touch sensitivity

Resistive touchscreens provide excellent touch sensitivity, enabling users to perform actions such as tapping, swiping, and pinching gestures. They are also capable of detecting multiple points of contact simultaneously, allowing for multi-touch functionality.

IV. Applications of Resistive Touchscreens

● Industrial and manufacturing environments

Resistive touchscreens find extensive use in industrial automation and control systems, where they are exposed to harsh conditions and require high durability and accuracy.

● Public information kiosks

It is popular in public information kiosks, allowing users to access information and navigate through interactive menus with ease.

● Medical and healthcare devices

It is widely used in medical devices like patient monitoring systems, diagnostic equipment, and handheld medical devices due to its accuracy, versatility, and ease of cleaning.

● Point-of-Sale (POS) systems

It is commonly employed in POS systems, enabling fast and accurate input for retail transactions.

● Consumer electronics and mobile devices

Though capacitive touchscreens have gained popularity in consumer electronics, resistive touchscreens still find applications in rugged devices, handheld gaming consoles, and certain specialized devices.

V. Conclusion

Resistive touchscreens are versatile and widely used touch-sensitive display technology. They offer high accuracy, durability, and versatility, making them suitable for various applications.

As technology continues to advance, resistive touchscreens may see further improvements in terms of touch sensitivity, response time, and durability. Integration with other technologies like haptic feedback and gesture recognition may enhance user experiences.

As technology continues to advance, we can expect further innovations in resistive touchscreen.