#Industry News

RELIABLE PACKING FOR SEAMLESS STEEL PIPE

hexagonal-shaped packing for the pipe

The way of packing steel pipes in the seamless steel pipe finishing line has a great influence on the factory image and quality of the products, therefore, most famous steel factories takes steel pipes packing very seriously, a good way of packing will be helpful for loading, transporting, storing and stacking application of pipes, especially for those small diameter steel pipes.

There are 3 types of packing steel pipes in general, which are random packing, container and bundling packing. Random packing is normally for the steel pipes of which the diameter is greater than 159mm and the profiled bars of which the cross-section circumference is more than 500mm, container packing is often used for thin-walled welded pipes with thickness less than 1mm.

Inspection, Packing And Quality Certificate For The Steel Pipe ( GB/T 2102—2006) [1] specified in China’s national standard that the steel pipes should be bundled and strapped before shipping, it clearly made the following statements, first, for each bundle of steel pipes, it should be of the same batch(except for the permitted mixed batch ), secondly, the weight of polished steel pipes, high precise steel pipes and cold rolled stainless steel pipes for each bundle must not exceed 2,500kg, and its weight is not allowed to exceed 5,000kg for the other types of steel pipes (there is an exception when the sellers and buyers made an agreement about the weight of steel pips).

The Picture 1 given below demonstrates the types of the steel pipes packing, the figure a/b/c/d respectively represents the four different types, which are rectangular packing, frame packing, general packing and hexagonal packing, the distance from strapping position to both end of the steel pipes should be over 300-500mm, and the distance between each strapping position of the bundle should be even, the number of the bundle should follow the chart 1 given below.

Picture 1

rectangular packing, frame packing, general packing, hexagonal packing

Table 1

The length of steel pipes/m The minimum strapping positions per bundle

≤3 2

> 3 ~ 4. 5 3

> 4. 5 ~ 7 4

> 7 ~ 10 5

> 10 6

The features of the hexagonal-shaped packing for the pipes are: it’s more economic and trouble-saving than framed packing, and it’s of better appearance and more weight-withstanding than general packing, moreover, it’s much easier to count the quantity of pipes.

To sum up, the hexagon-shaped packing of steel pipes is more reliable compared with other ways of packing, because of such advantages of the hexagon-shaped pipe packing, more and more factories in metal & metallurgy industry bring in the automatic hexagon-shaped packing system to their steel pipe factories, especially for high quality steel pipes.

The procedures of automatic hexagon-shaped packing for steel pipes are stated as below:

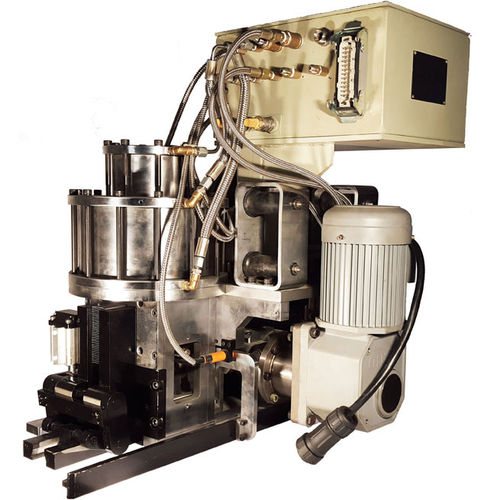

The steel pipe on the production line is transported to the alignment station via a conveyor chain, the automatic electromagnetic adsorption equipment lifts and stacks the steel pipes layer by layer to the brace type bundling equipment to form a hexagon shape of steel pipe bundle, after that, the brace type bundling equipment moves until it’s in line with strapping station, and then conveys the steel pipe bundle during strapping for the automatic strapping machine banding on different positions, when packing process is done, the strapped steel pipe bundle will be conveyed to the storage rack by carrier cart or chain storage conveyor waiting to be transported to the warehouse.

pipe strapping process, pipe bundling process

In order to improve the working efficiency of the bundling machine, the system adopts a combination of sequential operation mode and parallel mode,which is, the bundling of steel pipes by automatic electromagnetic adsorption equipment and preparation of the next layer of steel pipes can be carried out simultaneously, besides, the bundling equipment can prepare the next bundle of steel pipes during the process of the steel pipe being transported by the carrier cart to the storage station.

All in all, this automatic hexagonal packing system for steel pipes features higher efficiency and better packaging quality and more cost-effective than other ways of packing in the industry. The automatic pipe packing system is very practical and maintenance-free, which has been largely brought into large workshops of steel pipes since its development.