#Product Trends

Motor for Cordless Handheld Vacuum Cleaners

Modified & Custom Solutions, Manufacturers & Suppliers

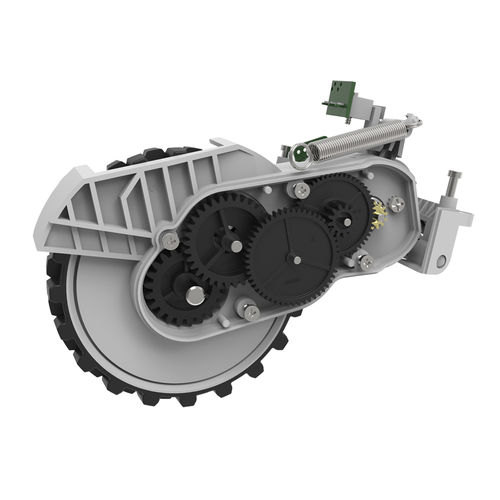

As the representative of cleaning products, handheld vacuum cleaners occupy an important position in small home appliances. But owing to its small power, the suction is not strong enough. Generally speaking, the cleaning capacity of a vacuum cleaner is related to its structure of roller brush, design, and motor suction. The greater the suction it has, the better the cleaning effect it will get, but the power consumption and noise will accordingly increase. ZHAOWEI roller brush gear motor module for a vacuum cleaner is mainly used for the driving wheel, main brush, side brush, and other moving parts of the vacuum cleaner to meet the requirements of low noise, long service life, and ideal efficiency.

As consumption upgrades, household vacuum cleaners, especially cordless handheld vacuum cleaners, have been gaining more and more popularity owing to its convenient use without any cord. Cleaning power is an important factor that must be considered when purchasing. Nowadays, most of the vacuum cleaners on the market operate by connecting the vacuum cleaner with the connector on its tube. This features poor flexibility, a lack of flexible rotation, and weak suction. Besides, the brush head will be easy to fall off and not easy to install, resulting in inconvenient use.

To solve the problems above, ZHAOWEI together with smart home appliances manufacturers found that there is still much room for improvement in dust collection of cordless handheld vacuum cleaners based on research & development. By adding the high-torque planetary gear motor to the suction head of the brush, the suction power will be improved, the service life will be extended and the noise will be reduced when using.

Design Principle of Rotating Module for Cordless Handheld Vacuum Cleaners

Although there are many types of cordless handheld vacuum cleaners, they have a similar structure which is composed of shell, motor, automatic charging base, virtual wall transmitter, sensor head, switch, electric brush, dust bag, etc. At present, most vacuum cleaner motors mainly adopt AC series excitation motors and permanent magnet DC brush motors, both of whose service life is confined to the service life of carbon brush. This leads to short service life, large size, and weight, as well as low efficiency, which cannot meet the market demand well.

Based on the motor requirements of vacuum cleaner industry (compact size, lightweight, long service life, and high performance), by adding the high-torque planetary gear motor to the suction head of the brush, ZHAOWEI takes advantage of the rotating module for cordless handheld vacuum cleaners to control the motor to drive the blade to operate at high speed and simultaneously supplement intake fan with the air in dust collection part. The instantaneous vacuum will be achieved in the dust collector, which results in the negative pressure gradient with the external atmosphere. Under the action of this pressure gradient, the dust and dirt inhaled with the air will be filtered through the dust filter to collect them into the dust tube. The larger the negative pressure gradient it is, the stronger the air volume it will have, thus the greater the suction capacity it will have. This design enables ultrastrong suction of cordless handheld vacuum cleaners and endurable power source so that the brushless motor in the vacuum cleaner takes pride in large suction capacity, high power and low noise, which can be applied to most of the floors, floor tiles, floor mats, and short-haired carpets. At the same time, the soft velvet roller tackles hair easily, contributing to deep cleaning.

Generally speaking, the floor needs the most frequent cleaning, so for the rolling brush configuration, the 4-stage roller brush gear motor with powerful suction capacity can be chosen to quickly absorb the dust on the ground. ZHAOWEI has firmly committed to the roller brush gear motor design of the vacuum cleaner. 1-stage, 2-stage, 3-stage, and 4-stage transmission are available for the roller brush gear motor module while the gear ratio, input speed, torque, etc. can be customized according to customers’ transmission demands. This helps to meet the needs of intelligent transmission at all levels and enable dust removal in the scenarios with different degree of fouling.

Stable, Low-Noise, Reliable

In recent years, handheld vacuum cleaners continue to challenge other categories of vacuum cleaners and its retail sales ratio in overall vacuum cleaners continue to climb. In the early stage of the handheld vacuum cleaners market, the update and breakthrough of handheld vacuum cleaners by manufacturers were mainly on the premise of improving the suction capacity of vacuum cleaners. After the suction capacity develops to a certain degree, manufacturers begin to pay attention to the development of other subsidiary functions, such as product weight, the function of the brush head, anti-winding technology, multi-functional applications, and so on, in order to improve the user experience to a greater extent.

In order to avoid the motor damage caused by hair winding into the driving device, we optimized the structure of the main brush gear motor of the vacuum cleaner. Side brush gear motor relies on the meshing of the driving gear and driven gear to transmit the motion and power. Compared with other transmissions, it features wide adaptability, high efficiency, reliable operation, long service life, ability to transfer motion between any two axes in space, high precision of gears, low noise and small vibration.

The development of science and technology has freed man from the repeated movement of mechanization, and in some ways, it did even better than man. More and more characteristic vacuum cleaners in the market segment are available for consumers’ choice while seeking for a breakthrough in the new market segment has become an important aspect for handheld vacuum cleaners manufacturers when considering the future layout. ZHAOWEI vacuum cleaner gear motor module is mainly used for the driving wheel, main brush, side brush and other moving parts of the vacuum cleaner to realize low noise, long service life, high efficiency, etc.