#Industry News

Optical reader optimizes production processes and supply chains

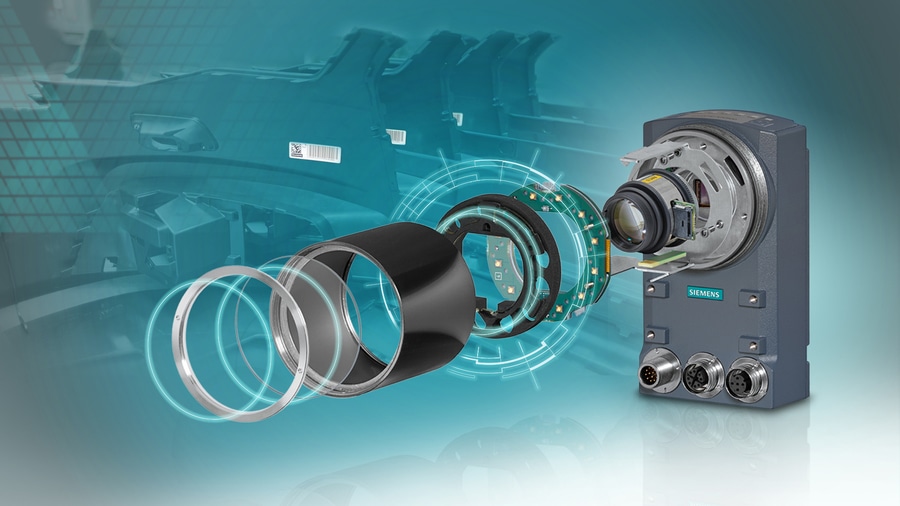

SIMATIC MV550

Siemens has introduced the Simatic MV550, the second optical reader in its new high-end Simatic MV500 series. The device is characterized by higher computing power, which allows a fast reading process and increased reading reliability – even under difficult conditions. It has an additional Gigabit Ethernet interface for diagnostic and service purposes. The Simatic MV500 can be easily and securely connected to cloud applications. This enables users to optimize production processes and supply chains, and to increase the efficiency and quality of production, logistics and asset management.

The additional Gigabit Ethernet interface transfers data at a rate of up to 1 Gbps. Images that are recorded in applications at a very high reading rate can be transferred to and archived on an IT server. This is the only way of ensuring faultless error diagnosis in high-speed production plants. At the same time, it increases plant availability by reducing downtimes. If the interface is not used for diagnostics, a PC can be directly connected to perform service and maintenance work via the web browser. The additional Gigabit Ethernet interface also facilitates network separation. This prevents the two data flows (from the camera to the controller and from the camera to the server) from influencing each other, which gives interference-free communication.

With the introduction of the Simatic MV550, Siemens has also significantly extended the accessory portfolio for the entire Simatic MV500 series. For example, additional e-focus lenses are available with different focal distances and ring lights in additional light colors and designs. This significantly expands the range of possible applications. The e-focus lenses make the "electronic focusing" function available to the optical readers. The flexibly controllable built-in ring lights allow readers to automatically adapt to product and ambient conditions, for example different incidence directions. The extensive range of accessories allows the devices to be automatically adapted to changing production conditions. This reduces incorrect parameterization during commissioning and contributes toward very high reading reliability and consequently to reduced downtimes.

Device configuration by web-based management and integration into the TIA Portal make an easy job of configuration. The one-button configuration for network and reading parameters makes the commissioning of Simatic MV500 devices particularly simple. The readers' high degree of protection (IP67) and their rugged construction make them especially suitable for use in harsh industrial environments. The modular setup of the products allows flexible adaptation to a very wide range of application requirements.

Like the Simatic MV540, the first device in the Simatic MV500 series, the Simatic MV550 can be securely and simply connected via the Simatic S7-1500 controller and the CP 1545-1 communications processor to cloud applications such as MindSphere, the open, cloud-based IoT operating system. Operating data, such as product identification and quality data with position and time, can be transferred to the cloud and recorded statistically to optimize production processes and supply chains.