#Product Trends

Modular Hamburger Production Line

Flexibility in hard- and software with SIGMATEK

The order from a premium customer stated: In less than 6 months, construct a complete production line for a factory in the USA. The task was to hygienically pack ground beef in the form of hamburger patties and ship them to approximately 80 Lidl stores. The result from Sleegers Technique, with the know-how from SigmaControl and SIGMATEK, is a 40-meter-long production line in which approximately 20 function units are flexibly connected with one another. The entire hard- and software for the control also came from the complete systems manufacturer.

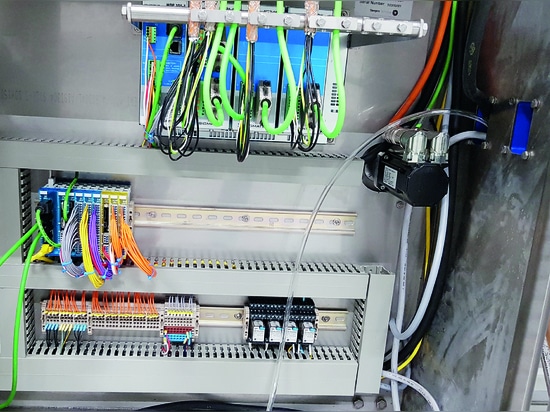

Sleegers project manager Jeroen van Beurden is thrilled. “A multi-touch HMI to operate the line, all function units are networked with one another and all data is stored in a common data bank. This is completely new since until now, each module had its own program and display, as well as its own recipes. We are happy that in all of our modular units, we can now install the super compact CPU and I/O modules from SIGMATEK’s S-DIAS series. In the object-oriented engineering software LASAL, these module blocks can also be directly configured and visualized in the hardware editor. Once created and tested, we can always reuse LASAL classes with minor changes. That saves an enormous amount of development time.”

In a packaging line, the Safety aspects also cannot be forgotten. When it comes to Safety, there is a complete SIL3-chain where emergency stop command devices and potential alarms can be clearly visualized on the operating panel. Says Jeroen van Beurden, “Several weeks ago, we had to solve a problem abroad. Over a live connection, we saw that the cause was a cable break in a safety switch that didn’t allow the machine to start. Within two hours, the problem could be solved from the Netherlands!”