#Product Trends

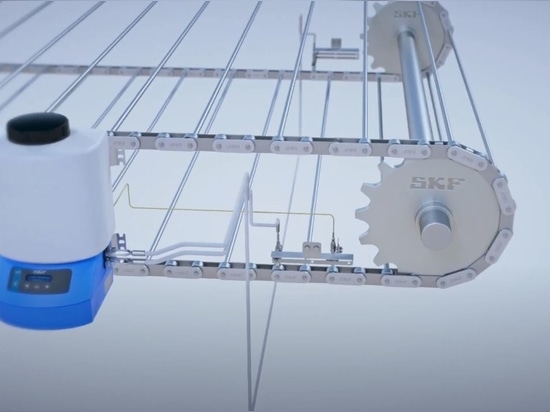

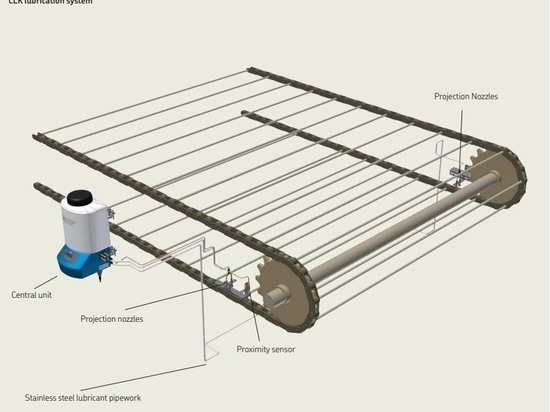

Food processing line lubrication system CLK

For hygienically lubricating the roller chains of industrial conveyors.

The CLK airless oil projection system is the simple, reliable, and easy-to-install solution for (hygienically) lubricating the roller chains of industrial conveyors.

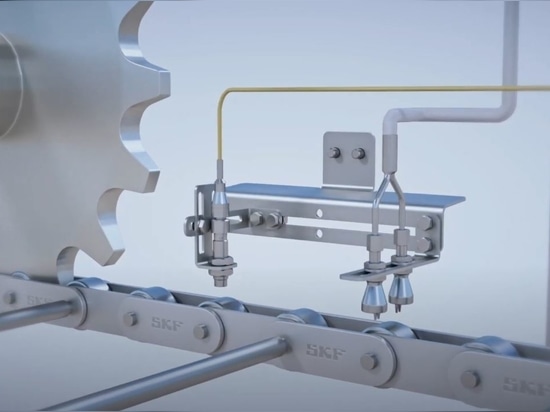

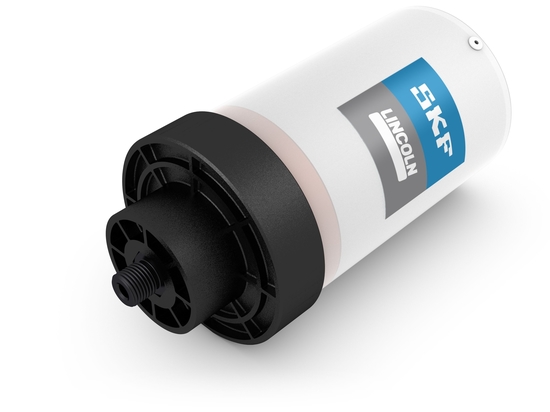

The system comprises a central unit with a reservoir, automatic system, and volumetric pump for delivering a precise quantity of lubricant through projection nozzles to each point of friction of moving chain links. None of the system components is in mechanical contact with the chain, thereby eliminating any risk of wear and potential build-up of dirt. Stainless steel components and a central unit design following hygienic design common rules, make this lubrication system suitable for food and beverage industry requirements. All components are corrosion resistant and easy to clean because of IP65 rating. Nozzles, pipework and lubricants are suitable for high (220 °C/430 °F) temperatures.

The CLK Application Configurator helps you to get the right SKF Chain Lubrication System CLK for your application. You will be informed if your application can be served with a CLK system. You will get the exact order number and you can download CAD files of the right CLK system for your application.

The CLK Programming Tool gives you the correct values to properly program the CLK to your application (refer to page 20/21 of the manual). At the end of the form, you can download the values to your device.

Features and benefits:

- Reduces maintenance costs

- Improves productivity by eliminating unscheduled downtime

- Lengthens service life as a result of reduced chain wear

- Reduces energy consumption through decreased friction

- suitable for high temperature (180° - 220°C) applications

- Optional: housing with heater for special applications

- fulfills hygienic requirements in food and beverage industry

- Supports HACCP process in safe food production

- Food grade oils (LFFM 100, LFFT 220) with requirements of food processing and pharmaceutical industries (NSF H1, NSF ISO 21469, Halal and Kosher) available

- IP65 rating

- corrosion resistant and easy to clean

- Increases cleanliness by reducing excess lubricant

Applications:

- Chains with speed of max. 40m/min and chain pitches of 25mm to 250mm

- Industrial bakery oven chains and other high temperature (180°- 250°C) applications

- high-humidity applications

- Conveyors in wet areas

- Conveyors for grading, cleaning, cooking and pasteurising fruit and vegetables

- Oven/dryer chains in all types of industries

- Handling conveyors