#Product Trends

Laser Displacement Sensor

To satisfy the industrial challenges for superior quality and higher production rates, the adaptation of displacement sensors decreases production time and cost while subsequently reducing human errors.

Industry Challenges

In a world of Industry 4.0, precision measurement technology plays a crucial role to meet the increasing demand for automation of manufacturing, inspection processes, and ensuring reliable quality assurance. To satisfy the industrial challenges for superior quality and higher production rates, the adaptation of displacement sensors decreases production time and cost while subsequently reducing human errors. For example, the errors can be caused by equipment mishandling or management operations.

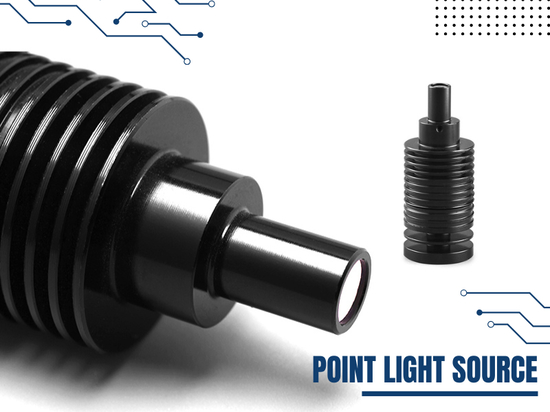

Product Description

SmartMore laser displacement sensor series is a high-precision non-contact displacement sensor based on the principle of laser triangulation distance measurement. The measurement accuracy of our laser displacement sensors is high. It has a direct/oblique compatible structure and can detect both diffuse reflective surfaces and specular reflective surfaces. Also available in humanized touch screen operation interface added in controller part, with a rich communication interface, which is convenient for users to use and later integrated development.

Main Feature and Benefits

● Ultra-high repetition accuracy ranging from ±0.25 to ±0.1 μ M (RMS)

● High linearity ranging from ± 0.02% to ±1%

● IP67 dust and waterproof ·

● Accurate, safe, fast, and cost-effective

● A built-in algorithm, suitable for a variety of reflectivity objects

● Z-axis high precision positioning of the wafer

● Wear-free, fast, high precision, and reliable measurements

Application Scenarios:

It is widely used in step height measurement, thickness measurement, wafer surface testing, flatness measurement, center pointing, positioning of the needle of the dispenser, CNC tool positioning, and the positioning of the industrial robot.

● The laser displacement sensor has an irreplaceable role in welding, blank manufacturing, mechanical processing, heat treatment, loading and unloading, assembly, and other operations.

● It can take exact geometric measurements such as displacement, thickness, vibration, distance, and diameter, as well as measurements of the position, displacement, and other changes of the object being measured.

● Can be used in factory automation, electronics production, robotics, chemical industry, medical technology, and machine construction.

● Excellent for use in engineering for quality control and process monitoring.

● Suitable in the detection of cracks in concrete.

To best satisfy the needs of multiple industries we provide the customization option for each product.