#Product Trends

How to select the right electrical connector for specific medical devices and applications

To ensure patient and provider safety, medical connectors must satisfy a variety of government and industry standards depending on the usage and specific applications.

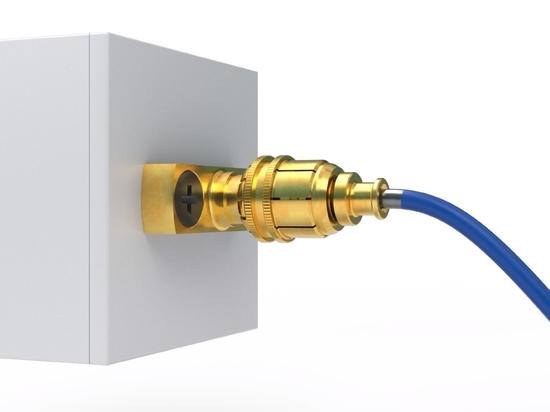

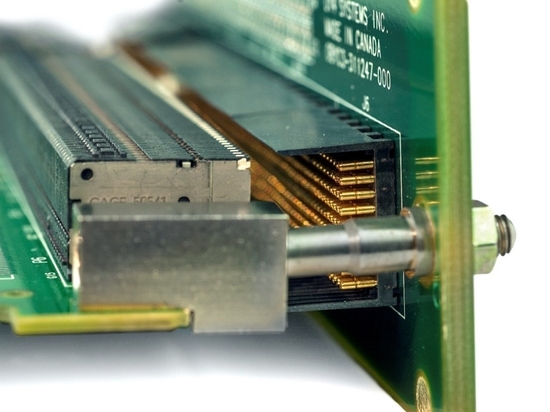

Electrical connectors are used in a variety of medical devices and applications ranging from very large and expensive machines, such as magnetic resonance imaging (MRI) systems to lower cost portable field devices such as defibrillators. Depending on the specific application, these connectors are engineered to satisfy different requirements for reliability and number of uses. This affects their design, manufacturing techniques, testing and materials, thus affecting the life cycle costs. It is imperative to understand the requirements for electrical medical connectors and how the design and cost of these connectors are affected by these requirements. Smiths Interconnect is a global provider of cutting-edge connectivity solutions, and the HyperGrip® series of high reliability medical connectors solves countless device requirements without compromising on industry needs.

Connectivity requirements

Medical connectors must be capable of transmitting power, signal or data from one cable to another in a safe, stable and hygienic manner. They must also be designed in a fool-proof manner to provide reliable connections and prevent unintended or erroneous connections. To ensure patient and provider safety, medical connectors must satisfy a variety of government and industry standards depending on the usage and specific applications:

The International Electrotechnical Commission (IEC) has developed general requirements for basic safety and performance for a wide range of medical electrical equipment and systems (IEC 60601-1), which is widely accepted in many countries throughout the world.

In the U.S., medical device manufacturers must demonstrate compliance with several requirements in the Premarket Approval (PMA).

The Ingress Protection rating (IP) is an international standard for rating how well an electrical connector can prevent ingress of dirt and water from reaching the contacts, which could present a potential hazard to patients and the medical equipment.

UL94 tests determine the flammability of plastic materials based on burning speed, burning time and dripping behavior, and the ability of the plastic material to extinguish the flame after it is ignited.

These and other standards provide guidelines for medical devices that affect numerous design characteristics, among those including material selection, maximum number of sterilization cycles, maximum number of mating cycles, minimum and maximum operating temperatures, EMI shielding and finger proofing. Conformance to these standards drives medical connector quality, performance and cost. For purposes of affordability, it is desirable to match the connector capabilities to the expected lifetime, cost and reliability of the medical equipment. For example, it may not be desirable to use a low-cost medical connector that is qualified to a limited number of sterilization cycles on high-cost medical equipment designed for numerous sterilization cycles, and vice versa. Medical device designers must therefore be cognizant of the medical device applications in which the connectors will be used, as well as the design, reliability and cost of the connectors themselves.