#Industry News

Blog Post

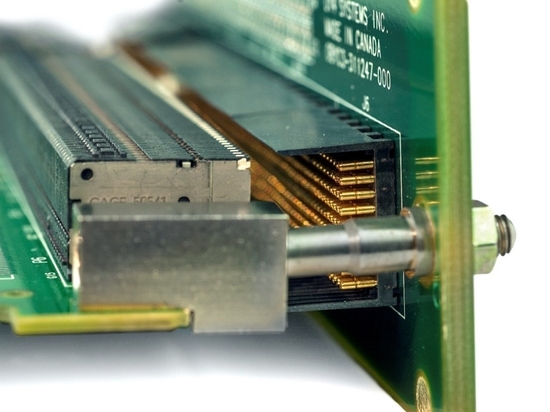

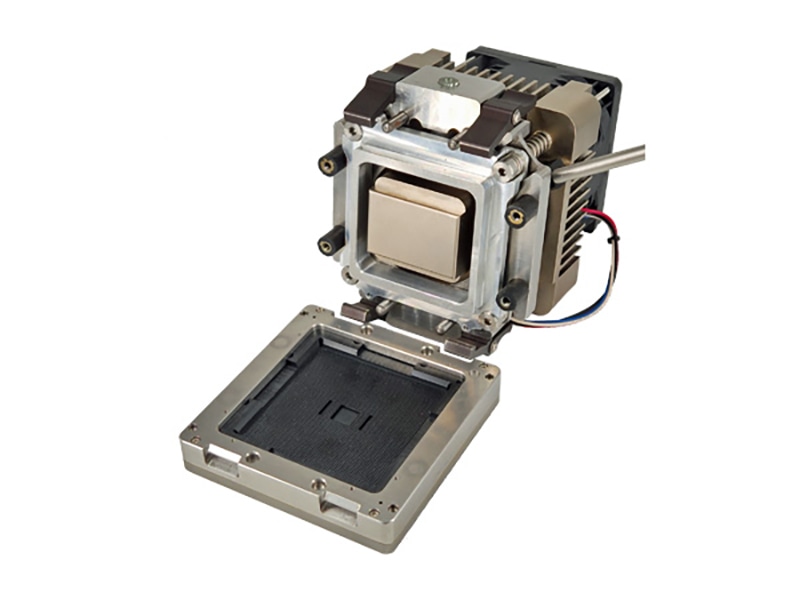

What is thermal simulation and why is it important to reliability burn-in testing?

Not every semiconductor manufacturer utilizes thermal simulation in their reliability testing setup. Lower power burn-in allows for an acceptable temperature rise within the package/die in a traditional burn-in chamber running at 125°C. As packages in burn-in are moving to higher power output, socket and burn-in systems may need to have enhanced features to manage the desired target die temps. At Smiths Interconnect, we conduct thermal simulation prior to burn-in board and socket manufacture to more effectively narrow down and identify necessary features for sockets and systems. Then, we’re set up for efficiency in the burn-in testing phase.