#Industry News

Automotive Industry

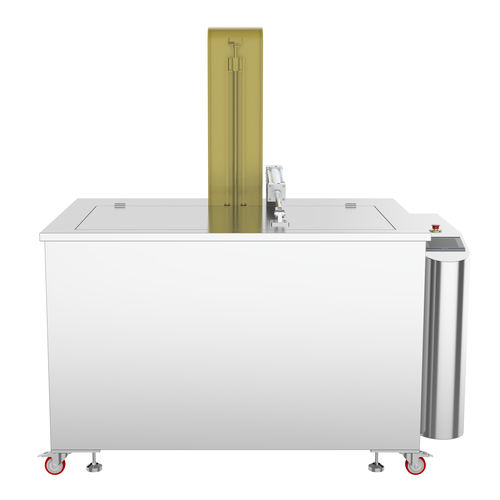

Enhancing Precision and Efficiency: Industrial Ultrasonic Cleaners in Automotive Industry

With its numerous parts and demand for precision, the automotive industry necessitates advanced cleaning processes. Thus, the industrial ultrasonic cleaner is a mechanism that has transformed the industry.

Due to their unparalleled precision in cleaning intricate and difficult-to-reach parts, industrial ultrasonic cleaners have discovered a vital function within the automotive industry. Consequently, these cleaners provide several significant benefits, including comprehensive cleaning of complicated components, reduced manual labor, excellent vehicle performance, and increased efficiency from manufacturing to maintenance.

Ultrasonic cleaning improves engine parts, transmissions, fuel injectors, carburetors, and various metal and plastic parts. Consequently, multiple pollutants frequently expose these parts during manufacturing, assembly, and use.

Here are some applications for the automotive industry: Engine and Transmission Components, Carburetors and Fuel Injectors, Brake Calipers and Wheel Cylinders, Bearings and Bushings.

Components used in the automotive industry are susceptible to a wide variety of pollutants, any of which have the potential to adversely influence performance, efficiency, and lifetime. Ultrasonic cleaners used in industry are very effective in removing pollutants such as: Oil and Grease, Carbon Deposits, Dirt and Grime, and Rust and Corrosion.

Contamination can have various detrimental impacts on vehicle components, including lower performance. Lower Performance: Dirt and dust can reduce the efficacy of engine parts or aerodynamic components. Wear and tear: Metal shavings, grease, and oil can all hasten the wear on an element, reducing its overall lifespan. Component failure or dysfunction can be caused by rust and oxidation; safety concerns might arise from contaminated brake or suspension parts.

Some Benefits of Industrial Ultrasonic Cleaning in the Automotive Industry Efficiency: Ultrasonic cleaners can handle several components simultaneously, cutting down on cleaning time. Exactness: When the cavitation bubbles created by the high-frequency sound waves come into contact with the surface, they burst. As a result, this process ensures the removal of even the smallest contaminants. Safety: Because they use less harsh chemicals, cleaning is safer for both the environment and the workers.

Although conventional cleaning techniques have aided the automobile industry for many years, introducing industrial ultrasonic cleaners has completely transformed how the industry cleans components. Ultrasonic cleaning is quickly becoming the industry standard for the repair of automobile parts because of its superior effectiveness, safety, and cost-effectiveness.