#Product Trends

Manufacturing a vital component for ventilators

Emergency medical production: Stäubli steps up

In the spring of 2020, France, like many other countries, was completely unprepared for the COVID-19 pandemic. Three industrial companies, MGA Technologies, Infiplast SAS and robot manufacturer Stäubli, recognized the need, reacted quickly and decided to jointly produce much-needed ventilator filters.

TASK

Manufacturing a vital component for ventilators

In March 2020, France was completely unprepared for the COVID-19 pandemic. French hospitals had only 5,000 ventilators available, and it was apparent that there would soon be a glaring shortage of consumables, including filters for ventilators. MGA Technologies, a custom machine manufacturer, proposed that the French government create a State stockpile of filters for ventilators to meet demand for several months or even several years.

Infiplast, a plastics manufacturer specializing in medical devices, was asked to produce a critical component for ventilators: the housing containing the heat and moisture exchanger (HME) filter. In order to respond quickly to government demand, Infiplast needed to set up a dedicated production line.

SOLUTION

Two robots for an ultra-efficient cell

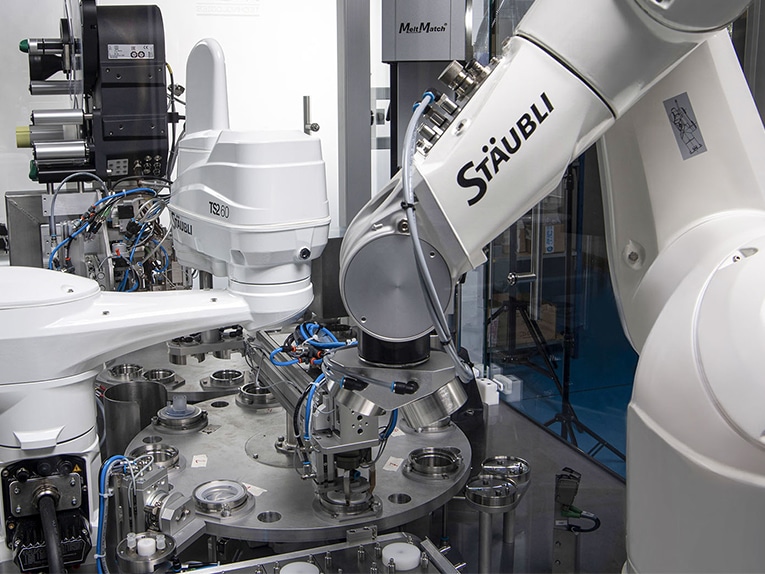

The use of robotics was inevitable. It became clear that two robots, a four-axis and a six-axis cleanroom model, were needed. Since Stäubli produces its robots in Faverges (Haute-Savoie) and they are tailored for medical technology due to their hygienic design, the right manufacturer was quickly identified.

Stäubli immediately responded to the request from MGA Technologies and Infiplast and provided the requisite robots in record time. This made it possible to get the entire system, from construction to commissioning, up and running in 10 weeks – a feat, considering such projects normally take at least 24 weeks.

Two Stäubli robots are used: a six-axis TX2-90 and a four-axis from the new TS2 series. The former collects the various plastic parts for the filter from the injection molding machine, and places the base of the housing and its cover on a rotary table. After inserting the foam and the membrane, the six-axis robot assembles the housing and places it on the ultrasonic welding station. The TS2 SCARA positions the housings for the final steps of testing and labelling. It then directs the compliant parts to packaging, and discards any non-compliant parts.

CUSTOMER USAGE

Sustainable, safe and highly productive filter manufacturing

The robot cell was integrated into Infiplast's production line in mid-July, making it possible to quickly build up a sufficient stockpile of HME filters for ventilators in French hospitals. Thanks to the short cycle time, a filter is assembled in a few seconds. The manufacturing of filters is now sustainable, and capacities are sufficient to supply filters on an international level. In addition, the cell’s integrated quality assurance system guarantees zero-defect production.

Another advantage of the compact system, which occupies only eight square meters of space, benefits employees: The handling of the repetitive tasks by the robots avoids hearing damage caused by tonal noise emitted during ultrasonic welding.

Infiplast filters are distributed under the PROPIUM brand. They contain a membrane that prevents cross-contamination between the patient and the ventilator, combined with a special foam that humidifies the air blown into the patient's lungs.